As an engineer at SuperPCBA, I am honored to introduce this article on PCB stiffeners with great enthusiasm and professionalism. In the modern electronics manufacturing field, PCB stiffeners are commonly used auxiliary materials to enhance the structural strength and stability of circuit boards. In this article, we will delve into the definitio

n, material classification, and construction methods of PCB stiffeners, aiming to present a comprehensive overview of this important auxiliary material and assist you in better applying it in practical production.

Definition

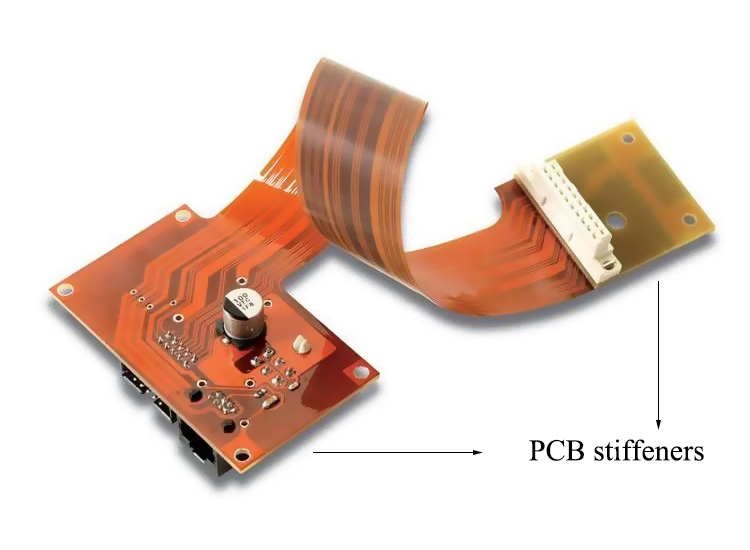

A PCB stiffener is a component commonly used to enhance the structural rigidity of flexible PCBs (Flexible Printed Circuit Boards) at the edges or specific areas.

Flexible PCBs are made of flexible base materials and have higher flexibility and bendability compared to traditional rigid PCBs. Therefore, flexible PCBs are more prone to bending and deformation. To enhance the structural rigidity and stability of flexible PCBs, and to prevent excessive bending or damage during installation or use, PCB stiffeners are used to provide additional support and reinforcement.

In addition to enhancing structural stability, stiffeners in flexible PCBs can also serve as assembly aids, helping to maintain the shape and flatness of the flexible PCB and providing a better working platform and precise positioning during assembly. Therefore, PCB stiffeners play an important role in the design and manufacturing of flexible PCBs, improving their reliability and stability.

Flexible PCBs that use PCB stiffeners can also be referred to as Rigid-Flex PCBs.

Material Classification

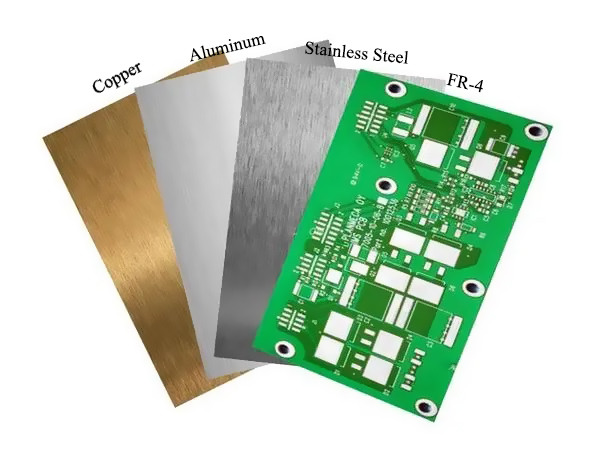

PCB stiffeners are typically made of rigid materials, and different materials can meet different design and functional needs. Here are some common PCB stiffener materials and their characteristics:

- FR-4 Glass Fiber Composite Material: FR-4 is a commonly used rigid PCB substrate material, composed of glass fibers and epoxy resin. FR-4 PCB stiffeners have good rigidity and mechanical strength, suitable for general PCB applications.

- Aluminum Alloy: Aluminum alloy is a lightweight, sturdy metal material with good thermal conductivity and corrosion resistance. Aluminum alloy PCB stiffeners are commonly used in applications requiring higher strength and durability, such as automotive electronics and aerospace.

- Stainless Steel: Stainless steel has excellent corrosion resistance and mechanical properties, suitable for PCB applications in various harsh environments. Stainless steel PCB stiffeners are typically used in applications requiring higher corrosion resistance and stability, such as marine equipment and medical devices.

- Polyimide (PI): Polyimide is a high-performance plastic material with excellent high-temperature performance and flexibility. PI PCB stiffeners are commonly used in PCB applications in high-temperature environments, such as aerospace, automotive electronics, and industrial control.

- Polyamide (PA): Polyamide is a plastic material with good mechanical properties and heat resistance, typically used in PCB stiffeners to provide lightweight and rigid support.

These are some common PCB stiffener materials, and the choice of suitable materials depends on the specific PCB design requirements and application scenarios. Different materials have different performance characteristics and applicable ranges, so the selection should be based on actual circumstances.

Construction Methods

How can PCB stiffeners be combined with Flex PCB? There are two common construction methods: thermal bonding and pressure-sensitive adhesive. Here are the specifics:

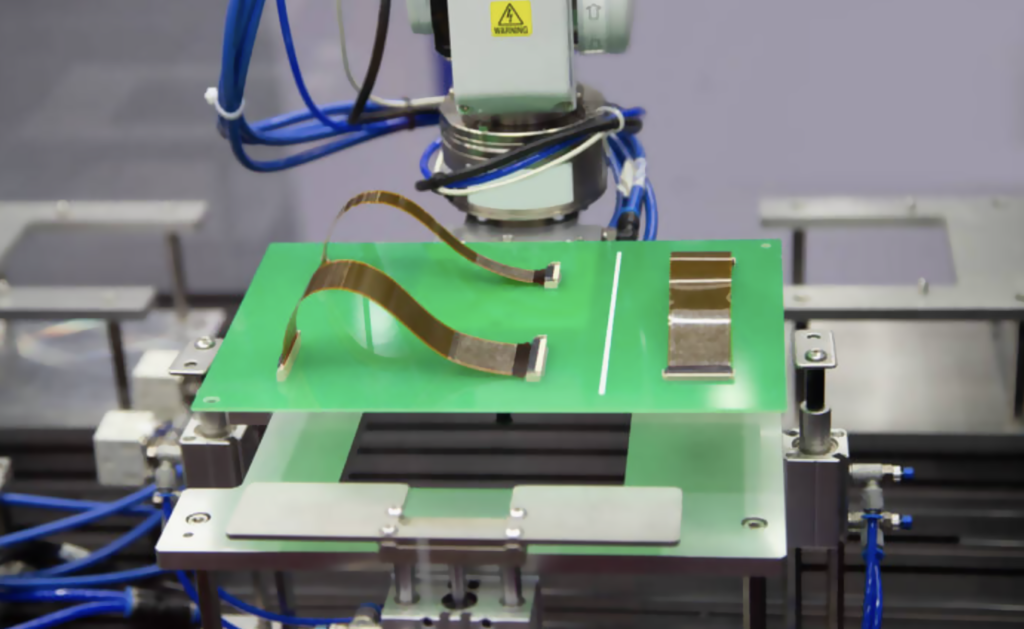

Thermal Bonding: Thermal bonding is a commonly used method where PCB stiffeners and the adhesive layer on the surface of the Flex PCB (usually a pressure-sensitive adhesive layer) are heated and bonded together. During this process, the PCB stiffener and Flex PCB are clamped together, then heated to a certain temperature to soften the adhesive layer and form a strong bond. Typically, this process is carried out in dedicated heat presses or thermal bonding equipment.

Pressure-sensitive Adhesive: Pressure-sensitive adhesive is a special type of adhesive layer that bonds under pressure. In this method, both the PCB stiffener and the Flex PCB surface are coated with pressure-sensitive adhesive layers, and then they are pressed together. The pressure-sensitive adhesive layer bonds together under pressure, forming a stable connection. This method does not require additional heating equipment and is typically carried out in a press or manually.

Now, let’s explore the characteristics and advantages of these two construction methods.

| Characteristics | Thermal Bonding | Pressure-sensitive Adhesive |

| Processing Temperature | Thermal bonding requires heating the PCB stiffener and Flex PCB to a certain temperature to soften the adhesive layer and achieve bonding. The processing temperature is usually relatively high, depending on the adhesive layer material, typically between about 120°C to 200°C. | Pressure-sensitive adhesive does not require additional heating equipment; room temperature is usually sufficient. |

| Processing Pressure: | During thermal bonding, a certain amount of pressure is typically applied to ensure the PCB stiffener and Flex PCB are fully adhered during the heating process. | Pressure-sensitive adhesive requires greater processing pressure to ensure the PCB stiffener and Flex PCB fully adhere. |

| Bonding Speed | Thermal bonding typically takes longer processing time, including heating and cooling processes, making the entire bonding process relatively slow. | Pressure-sensitive adhesive has a faster bonding speed since no additional heating steps are required; bonding is achieved simply by applying pressure. |

| Bonding Strength | Thermal bonding typically achieves higher bonding strength because the adhesive can fully wet the surface during heating, forming a strong bond. | The bonding strength of pressure-sensitive adhesive is relatively lower compared to thermal bonding, but in suitable applications, it can still provide sufficient bonding strength. |

| Advantages | 1. High Bonding Strength: Thermal bonding typically achieves high bonding strength, ensuring a strong connection between the PCB stiffener and Flex PCB. 2. Precise Control of Temperature and Time: By controlling the heating temperature and time, precise control of the bonding process can be achieved, ensuring bonding quality and stability. 3. Suitable for Mass Production: Thermal bonding is usually suitable for mass production requirements, enabling efficient and stable production. | 1. No Additional Heating Equipment Required: The PSA method does not require additional heating equipment, making the production process relatively simple and saving production costs and equipment investment. 2. Suitable for Small Batch Production and Rapid Prototyping: The PSA method is suitable for small batch production and rapid prototyping, enabling quick experimentation and validation. 3. Suitable for Various PCB and Flex PCB Materials: The PSA method has relatively lower requirements for PCB and Flex PCB materials, making it applicable to a wide range of materials. |

Thermal bonding and PSA differ in processing temperature, processing pressure, bonding speed, and bonding strength. The specific choice depends on factors such as PCB design requirements, production equipment, and application scenarios. Thermal bonding is suitable for mass production scenarios with high requirements for bonding strength and stability, while PSA is suitable for small batch production and rapid prototyping, with a wider range of applications but relatively lower bonding strength. The choice of method depends on specific production needs and product applications.

Conclusion

Through this article, we hope you have gained a deeper understanding of PCB stiffeners and can fully leverage their capabilities in practical applications. If you have any questions or cooperation needs in the field of PCB stiffeners or other related areas, we sincerely invite you to contact us at any time. Our email address is sales@superpcba.com. The SuperPCBA team is dedicated to providing professional consulting services tailored to your needs, offering you the best electronic manufacturing solutions. Let’s work together to create a better future and infuse your electronic products with greater stability and reliability!

Thank you for reading!