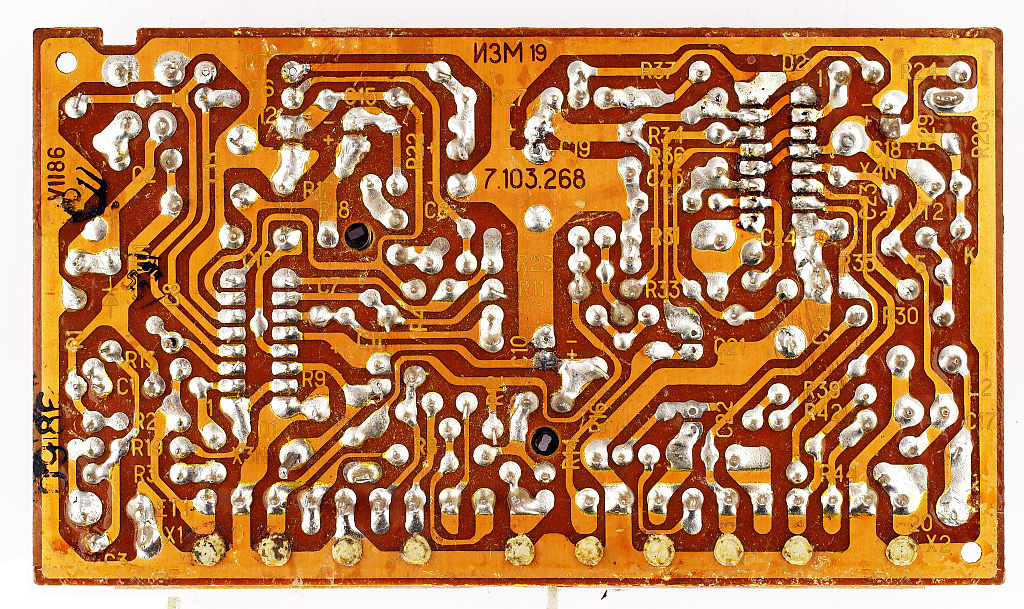

Through-hole PCB assembly is a traditional method of assembling electronic circuits where the components are inserted into drilled holes on a PCB and then soldered onto the board. Through-hole components have metal leads that are pushed through drilled holes in the PCB and then soldered to the opposite side of the board.

Through-hole PCB assembly is also a reliable and effective method of assembling electronic circuits, particularly for applications where the board is subjected to vibration or shock. However, it can be more time-consuming and labor-intensive than other methods of PCB assembly, particularly for boards with a high component density.

Through-hole PCB assembly has several characteristics that distinguish it from other methods of PCB assembly. For example:

Through-hole PCB assembly has several advantages over other methods of PCB assembly. For example:

Through-hole PCB assembly typically involves the following steps:

Get a factory directly price quote with 24 hours.

Pls input your email address correctly!

Make sure your name and email is right.