Testing and Inspection play very important role in PCB fabrication and Assembly processes. We always understand that customers require their PCB Assembly to be durable in long time run.

Early failures occur because of various types of issues that may happen during the manufacturing process, such as open and short circuits, Insufficient or excess solder, missing components, Misaligned components, wrong orientation, defective components etc.

SuperPCBA provides the testing and inspection services include AOI digital inspection, X-Ray, ICT in-circuit testing and FCT functional circuit test which ensure PCB assembly reliability.

Automated optical inspection (AOI) is an automated visual inspection of printed circuit board (PCB) manufacture where a camera autonomously scans the device under test for both catastrophic failure (e.g. missing component) and quality defects (e.g. fillet size or shape or component skew). It is commonly used in the manufacturing process because it is a non-contact test method. It is implemented at many stages through the manufacturing process including bare board inspection, solder paste inspection (SPI), pre-reflow and post-reflow as well as other stages.

X-Ray Inspection

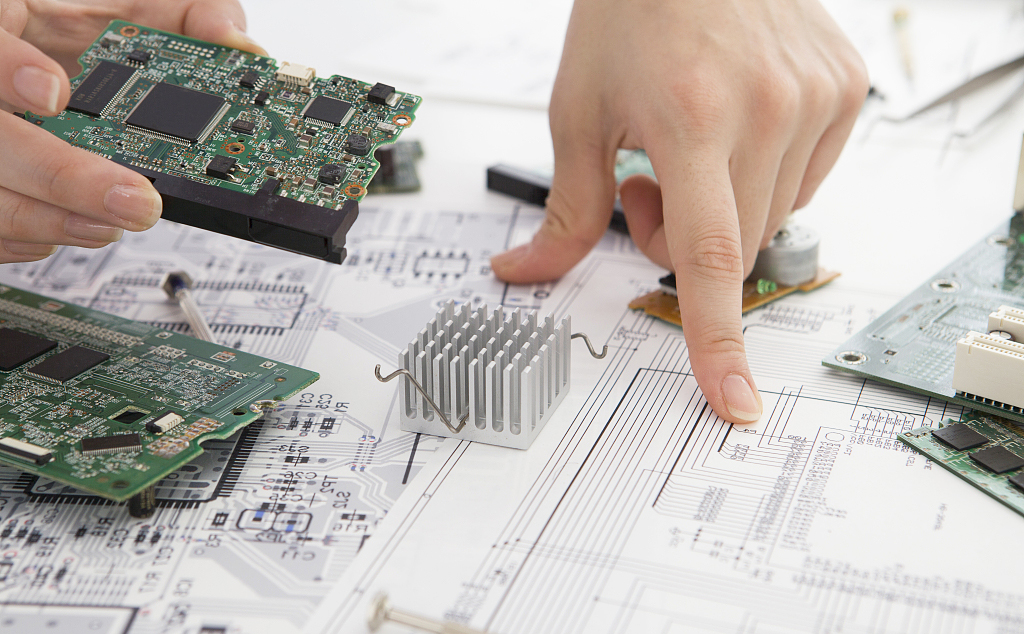

Auto X-ray Inspection has grown as a new type technology in PCB assembly inspection. Similar to optical inspection, X-ray inspection produces images of the PCBA object. The image is then processed by image processing software that detects the position and size and shape of expected features for process optimization or presence /absence of unexpected /unintended objects or features for anomaly detection. Instead of visible light, it uses X-rays, typically generated by an X-ray tube that pass through the object.

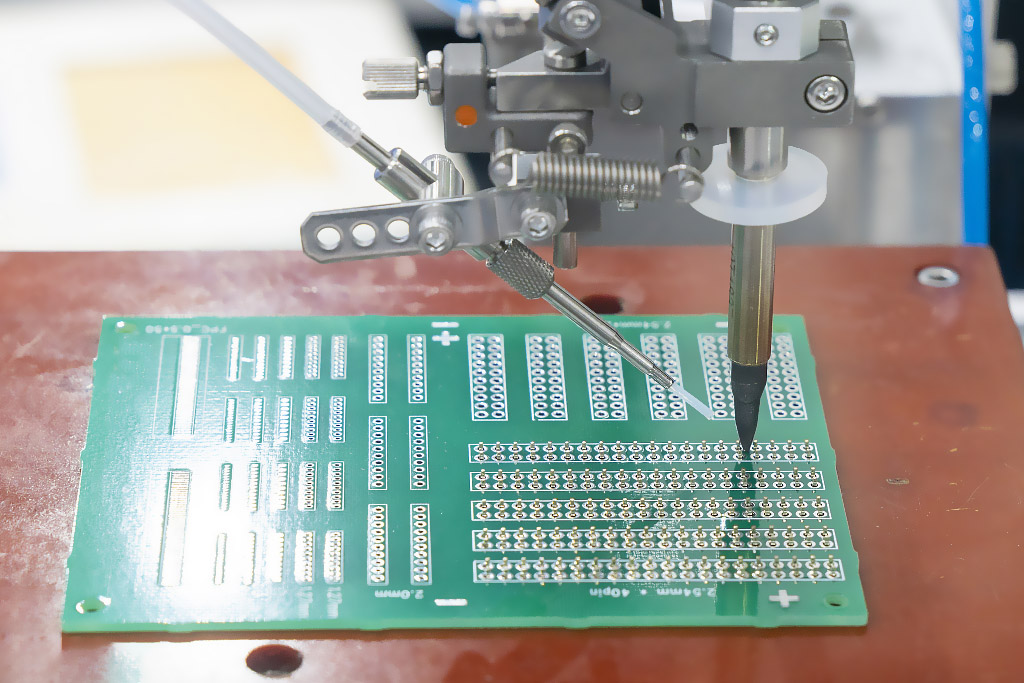

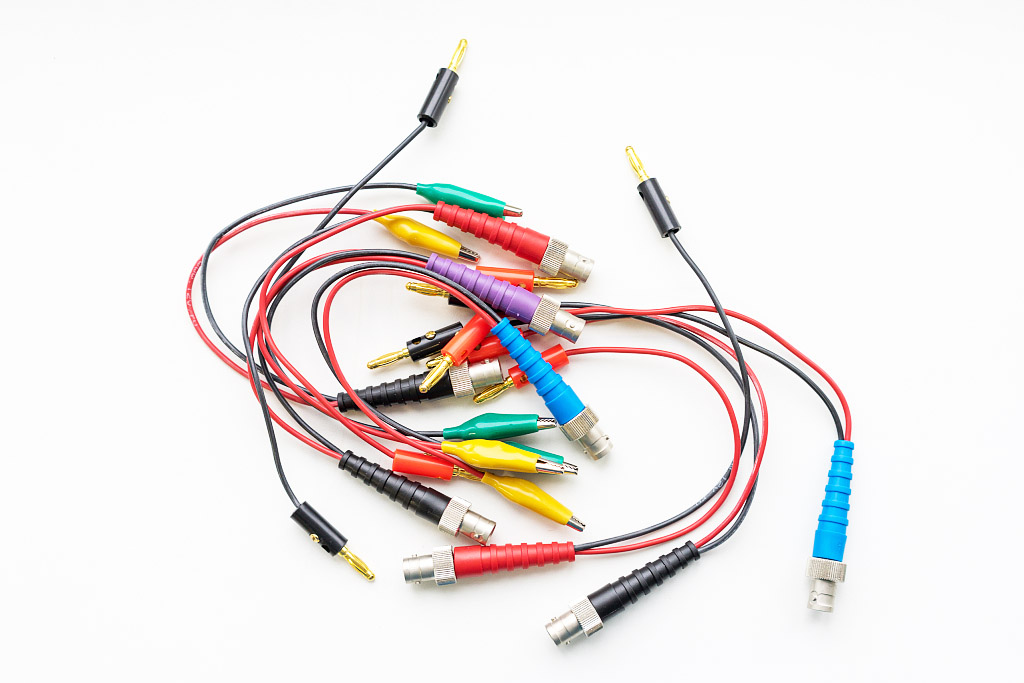

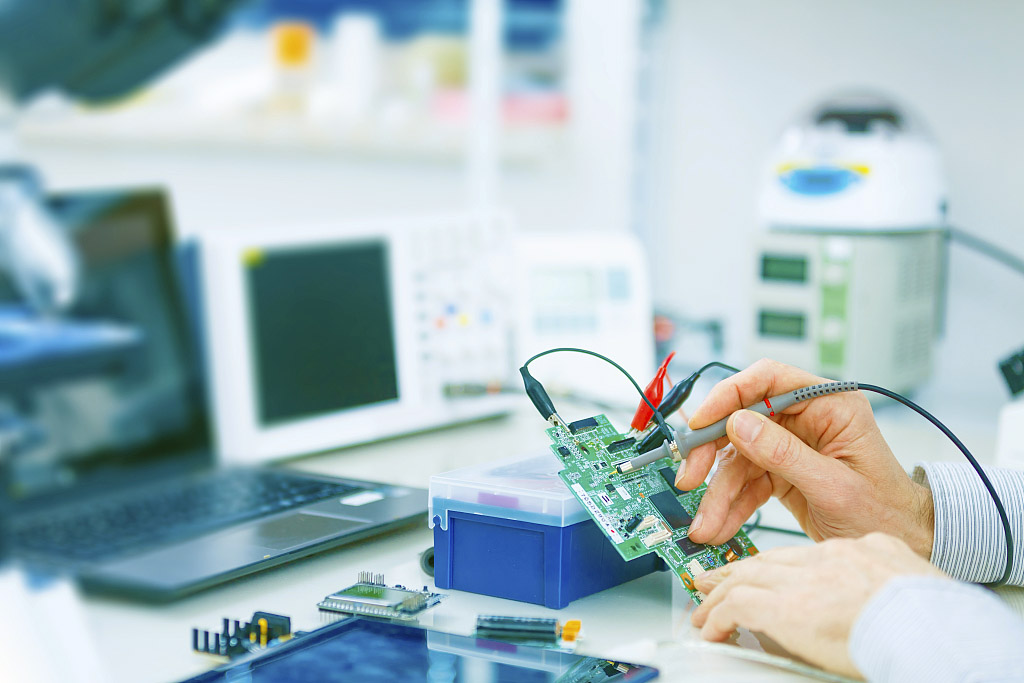

In-Circuit Test (ICT) is a standard test method to check the PCBA manufacturing defect and poor component by testing the electrical performance and connections of circuit components. It tests the soldering condition of the components, the on-off of the circuit, the value of voltage and current, the fluctuation curve, the amplitude, and the noise, etc.

Functional Testing(FCT)

The Functional Testing needs to carry out IC programming, simulate the function of the whole PCBA board, find the problems existing in the hardware and software, ensure the performance of PCB manufacturing and soldering. FCT testing pcb is also equipped with necessary production fixtures and test racks.

IC Programming

IC programming is the process of transferring a computer program into an integrated PCB Assembly. ICs are typically programmed in circuit though a serial protocol (sometimes JTAG sometimes something manufacturer specific). PCBA processing technology has become increasingly mature and has a wide range of applications. It plays a key role in today’s various intelligent devices. We can follow your required setting, configurations and the checksum provided to make sure all programming is done properly. IC programming, PCB assembly, coupled with our functional testing service will ensure that your software-driven PCB assemblies work exactly as intended every time.

Don’t hesitate to send us a request, we SuperPCBA will offer you one-stop-shop PCB assembly service at 7/24 hours.

Pls make sure the email information you filled in is correct, otherwise we won’t be able to reach you and give you a good offer.

Get a factory directly price quote with 24 hours.

Pls input your email address correctly!

Make sure your name and email is right.