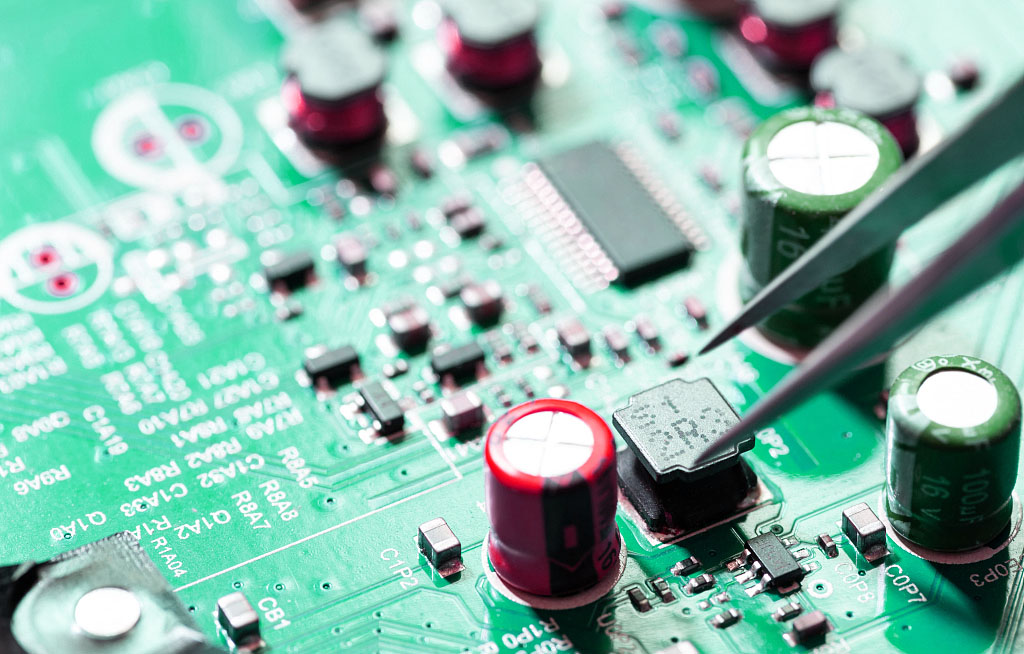

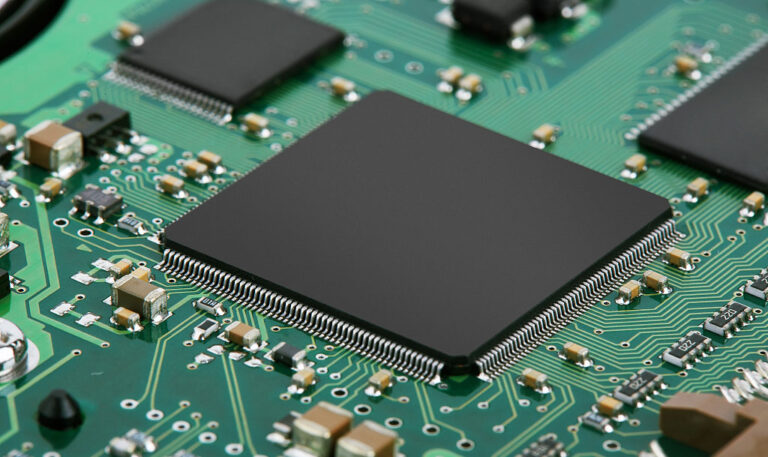

Surface mount PCB assembly is a method of assembling electronic components directly onto the surface of a printed circuit board (PCB) without drilling holes for through-hole components. It’s also called SMT PCB assembly. This method involves placing the components on the surface of the board and then soldering them in place using a reflow oven or other soldering equipment.

Surface mount PCB assembly is an important process for creating compact and reliable electronic devices that can be used in a wide range of applications, from consumer electronics to medical devices to aerospace and defense applications.

Surface mount PCB assembly is characterized by the use of smaller and more compact components, which allows for greater design flexibility and more efficient use of space on the PCB. The components used in surface mount assembly are typically smaller and lighter than through-hole components, and they may also be designed for higher levels of automation in the assembly process.

Surface mount PCB assembly offers several advantages over through-hole assembly, including:

| Items | SMT PCB Assembly | Through-Hole PCB Assembly | Remarks |

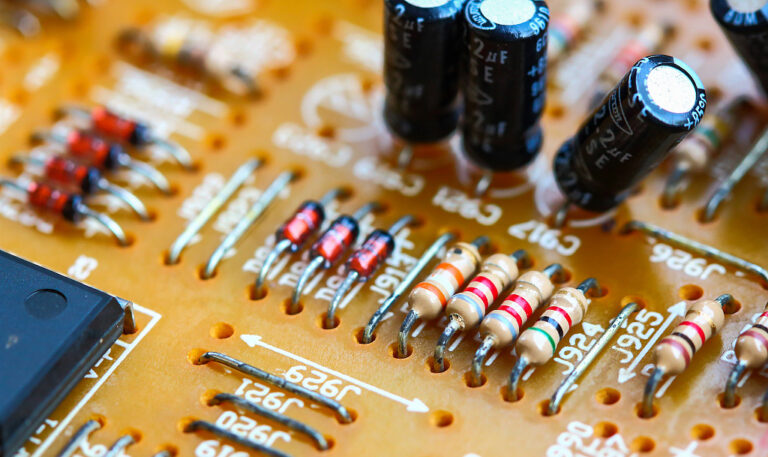

| Component Size | SMT PCB assembly uses smaller components. | Through-Hole PCB assembly uses bigger components. | SMT components are designed to be placed directly onto the surface of the PCB, whereas through-hole components are inserted into holes drilled into the PCB. |

| Assembly Process | SMT PCB assembly uses automated pick-and-place machines to place components on the PCB | Through-Hole PCB assembly usually requires manual placement and soldering. | SMT assembly is typically faster and more efficient than through-hole assembly. |

| PCB Design | SMT assembly allows for more compact and complex PCB designs. | Through-hole assembly, on the other hand, requires larger holes and more space on the PCB, which can limit design flexibility. | SMT assembly components are smaller size and it has the ability to place components on both sides of the PCB. |

| Reliability | SMT assembly can be more reliable than through-hole assembly because there are fewer mechanical stress points on the PCB. | Through-hole CPB components can sometimes become loose or break off due to vibration or thermal expansion. | SMT components are soldered directly onto the PCB surface. |

| Cost | The cost of SMT PCB assembly can be lower, especially for high-volume production runs | The cost of through-hole PCB assembly can be lower, especially for high-volume production runs | SMT assembly can be automated and requires less manual labor, whereas through-hole assembly requires more manual labor. |

| Repairability | SMT PCBs can be more difficult to repair. | Through-hole components can be removed and replaced more easily. | SMT PCBs components are very small and closely spaced. |

Overall, the choice between SMT and through-hole PCB assembly depends on the specific requirements of the application. SMT assembly is well-suited for high-volume production runs, compact designs, and applications that require high reliability. Through-hole assembly may be more appropriate for applications that require easy repairability, larger components, or higher mechanical stress resistance.

Surface mount PCB assembly can be done using a variety of methods, including:

Get a factory directly price quote with 24 hours.

Pls input your email address correctly!

Make sure your name and email is right.