As an engineer at SuperPCBA, I am pleased to present this article on plastic components for control boards. In modern electronic products, the control board is not just a collection of circuits and components; its associated plastic parts also play a crucial role in protecting and supporting the circuit board, enhancing overall product performance. This article provides a detailed exploration of the types, design, manufacturing, and application examples of plastic parts for control boards, offering comprehensive knowledge and reference for you.

Types of Plastic Parts

In the design and manufacturing process of control boards, injection-molded parts are indispensable components that provide mechanical support, protect electronic components, and realize various functional interfaces. Here are some common plastic parts associated with control boards:

- Enclosures and Protective Covers:

- Function: Provide mechanical protection, dustproofing, moisture resistance, and anti-static properties.

- Materials: Commonly used materials include ABS, PC, or PC+ABS.

- Design Considerations: Ensure sufficient strength while facilitating heat dissipation and maintenance.

- Buttons and Keypads:

- Function: User interface operations, such as preset modes and lift controls.

- Materials: Commonly made from silicone, ABS, etc.

- Design Considerations: Ensure good tactile feedback, clear response, and durability.

- Mounting Brackets and Clips:

- Function: Secure the control board to the bed frame or other supporting structures.

- Materials: Commonly used materials include PA (Nylon), PBT, etc.

- Design Considerations: Ensure easy installation, secure attachment, and high durability.

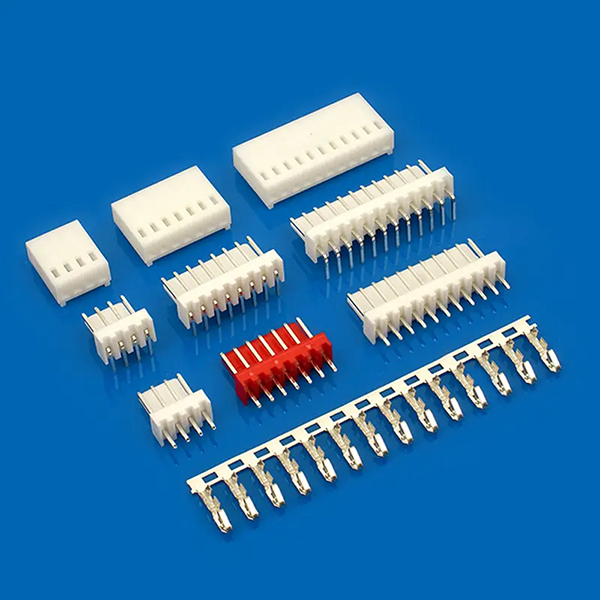

- Connectors and Terminal Blocks:

- Function: Connect cables, sensors, motors, and other external devices.

- Materials: Commonly made from PBT, PA, etc.

- Design Considerations: Ensure firm connections, good contact, and ease of installation and removal.

- Display Windows and Indicator Covers:

- Function: Protect displays and indicators while providing good visual effects.

- Materials: Commonly made from PC, PMMA, and other transparent materials.

- Design Considerations: Ensure high transparency, smooth surface, and wear resistance.

- Heat Sinks and Heat Shields:

- Function: Help dissipate heat from the control board, ensuring the circuit operates within a suitable temperature range.

- Materials: Commonly made from aluminum alloy, copper, and other metals; plastic parts are typically used for securing and thermal conduction.

- Design Considerations: Ensure high thermal efficiency, secure installation, and compact structure.

Design and Manufacturing Considerations for Plastic Parts

Different plastic parts serve various functions and have distinct material requirements. These need to be considered during the design phase. Attention must also be paid to details in every production step, such as mold design and surface treatment.

- Material Selection: Choose suitable materials based on specific functions and usage environments to ensure mechanical strength, electrical insulation, and durability.

- Dimensional Precision: Ensure high dimensional accuracy of injection-molded parts to fit well with control boards and other components.

- Mold Design: Consider the complexity of the shape, dimensional stability, and production efficiency of injection-molded parts, avoiding defects such as flash and air pockets.

- Surface Treatment: Perform necessary surface treatments, such as painting, printing, and polishing, to enhance appearance quality and functional performance.

- Reliability Testing: Conduct tests for mechanical strength, wear resistance, and weather resistance to ensure reliability in actual use.

Case Studies

Below are some examples of plastic parts, illustrating their specific roles in control boards, the materials chosen based on expected functions, and key design considerations.

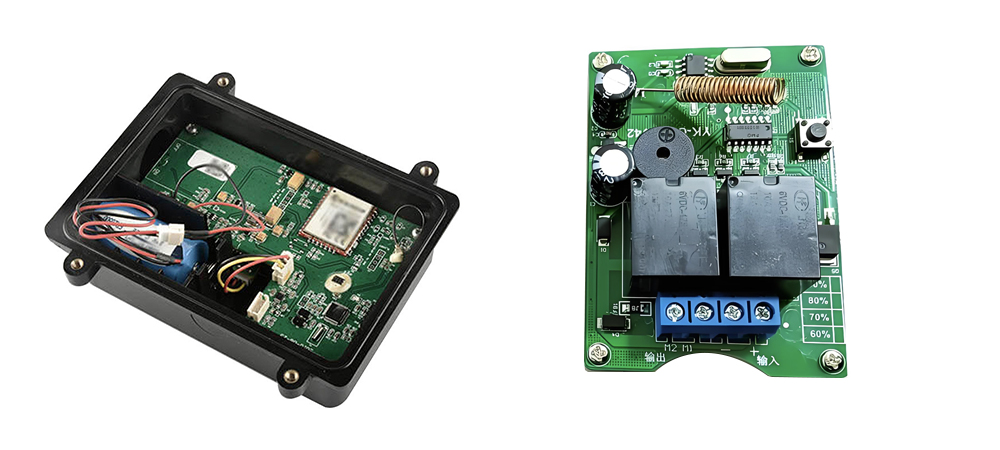

- Control Board Enclosure:

- Material: ABS+PC

- Function: Protect internal circuits, provide mounting structure

- Design Considerations: Reasonable layout of ventilation holes, convenient installation interfaces

- Example: Typically uses two-color injection molding to combine aesthetics and functionality

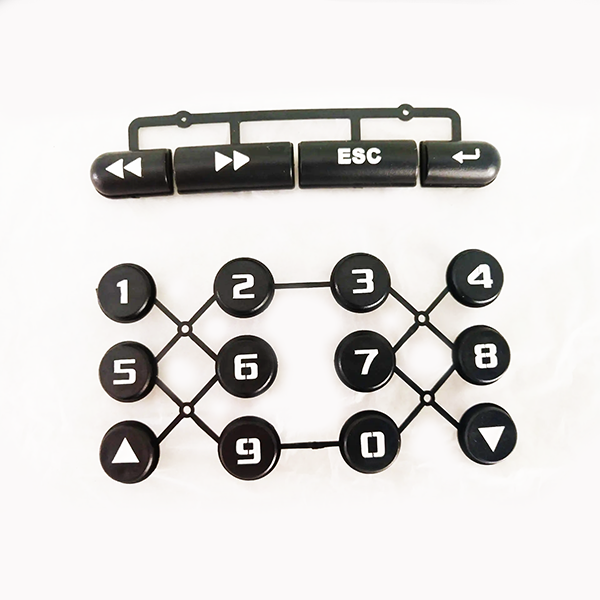

- Keypad Panel:

- Material: Silicone

- Function: Provide a user operation interface

- Design Considerations: Rational button layout, comfortable tactile feel

- Example: Uses laser engraving or painting to ensure clear markings

- Mounting Bracket:

- Material: PA66

- Function: Secure the control board to the bed frame

- Design Considerations: Stable structure, wear-resistant and durable

- Example: Can be designed as a detachable structure for easy maintenance

Conclusion

Through this detailed exploration, we hope you have gained a comprehensive understanding of the types, design, manufacturing, and application examples of plastic parts for control boards. High-quality design and manufacturing of associated plastic parts are crucial for ensuring the performance and durability of control boards.

SuperPCBA is dedicated to providing comprehensive electronic manufacturing solutions, with a professional technical team and advanced production equipment to meet your various needs for plastic parts for control boards. If you have any questions or requirements regarding plastic parts for control boards or other electronic manufacturing services, we sincerely invite you to contact us at sales@superpcba.com. We look forward to collaborating with you to create high-quality electronic products and support the success of your business.

Thank you for reading!