An air conditioner is an electrical appliance used for controlling and regulating the temperature, humidity, and air quality of a closed space, such as a room or building. It works by removing the hot air and moisture from the indoor air and replacing it with cool, dehumidified air. The process involves the circulation of refrigerant, which absorbs heat from the indoor air and releases it outside, resulting in a cooler and more comfortable indoor environment. Air conditioners are commonly used in residential, commercial, and industrial settings to provide a comfortable and healthy indoor environment.

The working system of an air conditioner typically involves the following components and steps:

- Thermostat: The thermostat senses the temperature in the room and signals the air conditioner to turn on or off as needed.

- Compressor: The compressor is the heart of the air conditioning system. It compresses and pumps refrigerant gas (usually Freon) from the outside unit to the indoor unit.

- Condenser: The condenser is located outside the building and is responsible for releasing the heat that was absorbed by the refrigerant in the indoor unit.

- Expansion valve: The expansion valve regulates the flow of refrigerant from the high-pressure side of the system to the low-pressure side.

- Evaporator: The evaporator is located in the indoor unit and absorbs heat from the air in the room, thereby cooling it.

- Blower: The blower circulates the cooled air throughout the room.

- Drainage system: As the air cools, moisture is removed from it, which can accumulate and create condensation. The drainage system ensures that the condensation is safely drained away from the unit.

Together, these components work to cool the air in a room or building and maintain a comfortable temperature.

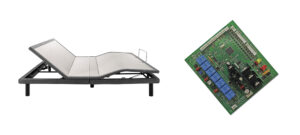

To keep the air conditioner system working well, a well designed and assembled PCB for air conditioner is needed.

Designing a PCB control board for an air conditioner involves several steps, which include:

- Define the requirements: Determine the requirements for the air conditioner control board based on the air conditioner’s features and functionality. Consider the input and output signals, temperature sensors, user interface, and other features.

- Select the microcontroller: Choose a microcontroller that meets the requirements for the air conditioner control board. Some factors to consider when selecting a microcontroller include performance, power consumption, memory size, and peripheral interfaces.

- Design the circuit schematic: Create a circuit schematic that includes all the components needed to implement the control board functions, such as the power supply, microcontroller, sensors, user interface, and other circuitry.

- Create the PCB layout: After the circuit schematic is complete, design the physical layout of the PCB. Consider the size of the board, the location of components, and the routing of signal traces.

- Prototype and test: Build a prototype of the control board and test its functionality. Identify any issues and revise the design as needed.

- Manufacturing: Once the design is finalized, create the PCB and assemble the components. Test the finished boards to ensure they meet the desired performance and functionality.

Overall, designing a control board for an air conditioner requires a thorough understanding of the system’s requirements and the ability to design a reliable and efficient circuit that meets those needs.

When designing a PCB control board for an air conditioner, there are several things to consider:

- Safety: The control board should be designed to ensure the safety of the user. This includes protection against electric shock, overcurrent, overvoltage, and short-circuits.

- Reliability: The control board should be designed to ensure the reliable operation of the air conditioner. This includes choosing high-quality components, and designing the board to withstand the operating conditions of the air conditioner.

- Size and layout: The control board should be designed to fit within the air conditioner unit, and the components should be arranged in a logical and efficient layout to minimize the size of the board.

- Power supply: The control board should be designed to receive power from the air conditioner’s power supply, and should include any necessary voltage regulators, filters, and protections.

- Communication: The control board should be designed to communicate with the user interface, sensors, and other components of the air conditioner. This may involve choosing the appropriate communication protocol and interface circuitry.

- Programming: The control board should be designed to allow for easy programming and updates. This may involve including a microcontroller or other programmable component, and designing the board to support firmware updates.

Overall, designing a PCB control board for an air conditioner requires a deep understanding of the system’s requirements, as well as expertise in electronic design and PCB layout. It is important to follow best practices and design guidelines to ensure a safe, reliable, and efficient product.

Above is our Turkish client’s air conditioning control board project. If you have a similar project, please contact us for a customized control board project solution. SuperPCBA will provide you with a reasonable solution based on your requirements, with the fastest turnaround time and the lowest price possible.