IoT Devices

The concept of the Internet of Things (IoT):

LoT devices refers to a technology and idea that connects various physical devices and objects together through the Internet, enabling them to communicate, exchange data, and achieve intelligent interactions. The core idea of the IoT is to equip everyday objects with Internet connectivity and intelligent processing capabilities, allowing them to automatically collect, transmit, and process data, thus enabling more intelligent, efficient, convenient, and secure services and applications.

The implementation of IoT functionalities:

To implement the function of LoT typically requires the design of corresponding control boards. The control board is a core component of IoT devices, integrating essential electronic components such as processors, memory, communication modules, sensor interfaces, etc., to handle the tasks and functionalities of the device. The design of the control board is tailored to meet the requirements and functional needs of IoT devices. It can be customized based on specific IoT application scenarios and functional requirements, such as smart homes, industrial automation, medical devices, and more.

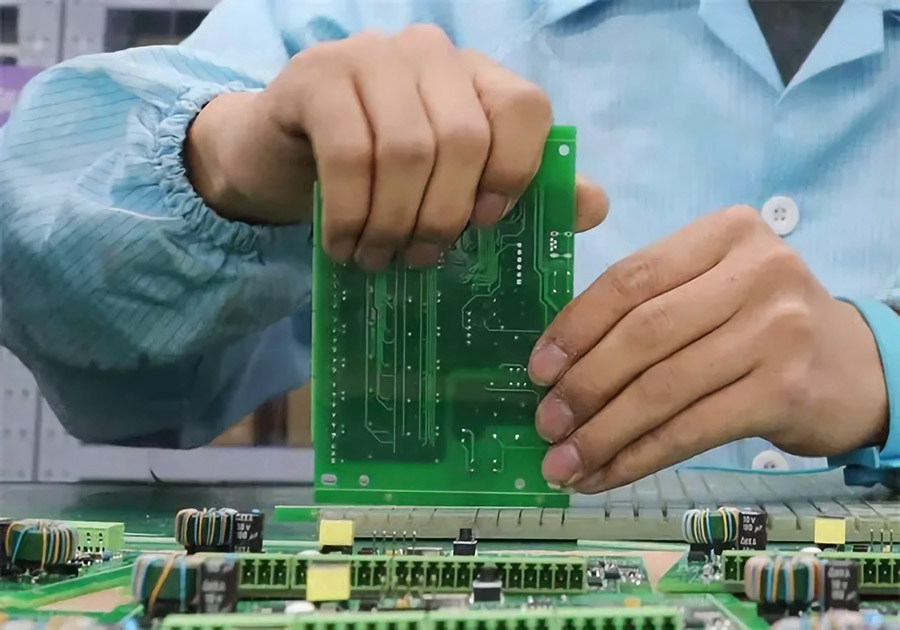

Assembly of IoT Devices Circuit Boards

Assembly of Regular Circuit Boards:

Circuit board assembly is the process of assembling electronic components (such as resistors, capacitors, integrated circuits, etc.) and other circuit elements (such as connectors, switches, etc.) onto a Printed Circuit Board (PCB) to form a complete electronic circuit. This process involves precisely soldering electronic components onto the PCB and ensuring they are correctly connected to create a functional circuit. It is typically divided into two main steps: 1. Surface Mount Technology (SMT); 2. Soldering.

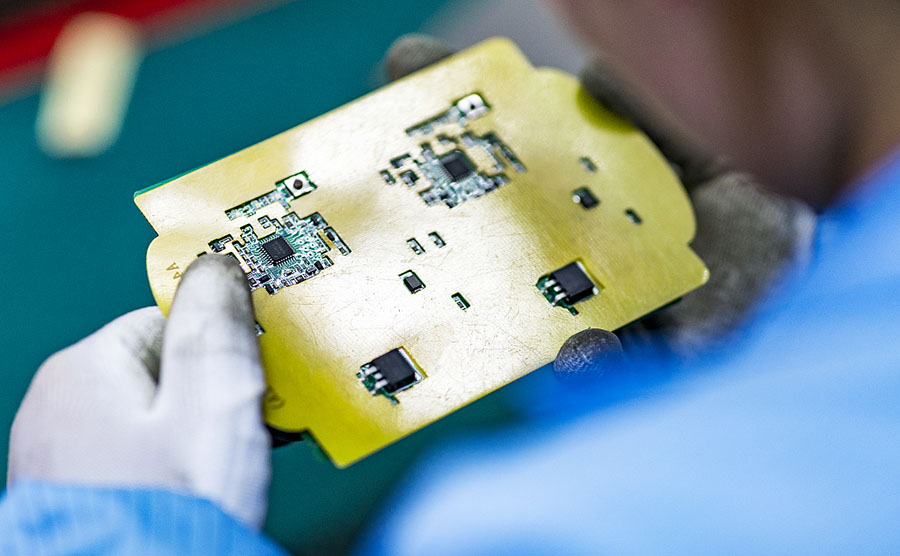

Assembly of IoT Devices Circuit Boards

The assembly of circuit boards with IoT functionality is similar to the assembly of regular circuit boards in general processes, but it requires additional attention to the specific requirements and features of IoT devices. As a result, the assembly of circuit boards with IoT functionality is more complex compared to regular circuit board assembly, as it involves considering multiple aspects such as hardware design, communication technology, low power consumption, data processing, and security. Through precise assembly, testing, and optimization, circuit boards with IoT functionality can achieve stable, secure, and efficient data transmission and communication, thus meeting the unique requirements and features of IoT devices.

Main Features of Circuit Board Assembly with IoT Functionality:

- Integration of IoT Functionality: IoT devices often require the integration of multiple functional modules and communication chips, such as wireless communication modules, sensors, processors, etc. In circuit board assembly, it is essential to ensure the precise layout and connection of these functional modules on the PCB.

- Integration of Communication Technology: IoT devices need to support various communication technologies, such as Wi-Fi, Bluetooth, Zigbee, etc., to enable communication with other devices or the internet. In circuit board assembly, the appropriate communication chips and antennas need to be added to ensure stable and reliable communication technology.

- Low Power Consumption and Energy Management: IoT devices usually rely on battery power, making power management critical. Circuit board assembly needs to optimize power management circuits, extend battery life, and ensure reliable operation in standby or low-power states.

- Data Processing and Storage: IoT devices generate a large amount of data, requiring data processing and storage capabilities. In circuit board assembly, it is essential to ensure that the device has sufficient memory and processing power to meet data processing demands.

- Security: IoT devices involve data transmission and privacy protection, making security a crucial consideration. Circuit board assembly needs to implement appropriate measures to ensure the secure transmission and storage of data, and prevent data leaks or unauthorized access.

- IoT Standards and Interoperability: IoT involves the interconnection of various devices and systems, necessitating compliance with IoT standards and protocols to ensure device interoperability and compatibility.

- Rapid Iteration and Updates: IoT technology develops rapidly, and devices require continuous updates and upgrades. Circuit board assembly needs to design a flexible architecture to facilitate rapid iteration and updates when necessary.

Challenges in IoT Devices Circuit Board Assembly

The assembly of circuit boards with IoT functionality faces several specific challenges, involving the complexity of IoT devices, communication requirements, power management, data processing, and security aspects. Here are some common challenges:

- Complexity and Integration: IoT devices often require the integration of multiple functional modules and communication chips, such as wireless communication modules, sensors, and processors. This increases the complexity of the circuit board, requiring careful planning of layouts and addressing interference issues among multiple modules.

- Communication Technology: IoT devices may need to support various communication technologies, such as Wi-Fi, Bluetooth, Zigbee, etc., to enable communication with other devices or the internet. Selecting the appropriate communication technology and ensuring its stability and compatibility present a challenge.

- Low Power and Energy Management: IoT devices typically rely on battery power, making power management crucial. Circuit board assembly needs to optimize power management circuits, extend battery life, and ensure reliable operation in standby or low-power states.

- Data Processing and Storage: IoT devices generate large amounts of data, requiring data processing and storage capabilities. Circuit board assembly needs to ensure that the device has sufficient memory and processing power to handle data processing demands effectively. Measures like high-performance processors, large-capacity memory, external storage support, data compression, and optimization can enhance IoT devices’ data processing and storage capabilities.

- Security: IoT devices involve data transmission and privacy protection, making security a critical challenge. Circuit board assembly needs to implement appropriate measures to ensure secure data transmission and storage, preventing data leakage or unauthorized access.

- IoT Standards and Interoperability: IoT involves connecting various devices and systems, necessitating compliance with IoT standards and protocols to ensure interoperability and compatibility among devices.

- Rapid Iteration and Updates: IoT technology evolves rapidly, leading to continuous updates and upgrades for devices. Circuit board assembly requires flexible architectures to facilitate quick iterations and updates when needed.

In summary, circuit board assembly with IoT functionality encounters higher technical complexity and diversity. Addressing these challenges requires comprehensive consideration of hardware design, software development, communication technology, and security aspects to ensure the stability, security, and performance of IoT devices.

Solutions to Challenges in IoT Devices Circuit Board Assembly

Facing the challenges of assembling circuit boards with IoT functionality, both the demand-side (customers) and the supply-side (factories) must adopt appropriate strategies to ensure the smooth progress of the project. The following strategies can be adopted:

Demand-Side (Customers):

- Clear Requirements: First and foremost, customers should have a clear understanding of their needs and objectives, including the functional requirements, communication technologies, power management, data processing, and security aspects of the IoT devices. For example, if the requirement is to have a smart temperature and humidity monitor with high-precision measurement capabilities, the customer should communicate specific requirements to the supplier, such as temperature measurement accuracy of ±0.2°C and humidity measurement accuracy of ±2%RH. Additionally, to meet the user’s real-time monitoring needs, the device uploads data to the cloud server every 10 minutes and displays it on the user’s mobile phone. To extend battery life, the smart monitor’s power consumption in standby mode should be kept below 100μA. Furthermore, the device should support remote control via a mobile app, allowing users to set alert thresholds. When the temperature or humidity exceeds the set values, the device will send alert notifications to the user.

- Choosing the Right Supplier: Select a circuit board supplier with extensive experience and expertise that can meet the specific requirements of IoT devices. Check the supplier’s qualifications and review customer feedback to ensure that the supplier has reliable production capabilities and quality assurance. For guidance on choosing the right supplier, refer to another article by SuperPCBA – How to Choose the Right PCBA Supplier: A Comprehensive Guide.

- Reasonable Project Timeline: Customers should collaborate with the supplier to plan a reasonable project timeline, ensuring that circuit board assembly and testing are completed within the designated timeframe to meet market demand and launch schedules. The project must be completed within 60 days, so it’s essential to communicate specific lead times for sample production, regular production, and testing with the supplier. Additionally, considering that sample testing may require multiple iterations and allowing time for improvements, as well as accounting for inspection and logistics time, all these aspects need to be taken into account. Dividing the timeline into appropriate milestones, closely monitoring the factory’s progress, and strictly adhering to the schedule are crucial to meeting market demand and launch schedules.

- Communication and Collaboration: Effective communication between customers and suppliers is vital. Customers should clearly convey their needs and requirements while actively listening to the supplier’s suggestions and feedback to collaboratively address issues and improve the efficiency and quality of circuit board assembly.

Suppliers (Factories):

- Technical Support: Suppliers should provide professional technical support, including expertise in hardware design, software development, communication technology, etc., to help customers solve technical challenges in the assembly of IoT circuit boards. For instance, if we are designing a smart light bulb that needs to support Wi-Fi, Bluetooth, and Zigbee communication technologies simultaneously to meet different users’ needs and application scenarios, this presents challenges in the layout of different communication modules to avoid interference. Additionally, selecting high-quality communication modules is crucial to ensure stable and compatible communication.

- Quality Control: Suppliers should establish a strict quality control system, including measures such as raw material procurement and inspection, production process control, testing and verification, sampling inspections, process monitoring, product traceability, and quality feedback. This ensures the stability and reliability of circuit board assembly. Rigorous testing and inspection should be conducted to ensure that the devices meet customer requirements and standards. This is a critical competitive advantage for the supplier and the foundation for customer trust and long-term cooperation.

- Continuous Innovation: IoT technology is constantly evolving, and suppliers should keep up with the latest trends and standards, continuously innovate and improve, and provide more advanced and intelligent solutions for circuit board assembly. For example, IoT devices with integrated voice assistant features, like Amazon Echo or Google Home, require modular design, programmable processors, and OTA update support during the assembly stage to enable quick iteration and updates when needed. This ensures that the devices remain advanced in functionality and performance amid the rapid development of IoT technology.

- Compliance and Security: Suppliers should ensure that IoT devices comply with relevant compliance standards and security requirements to safeguard user data and privacy. For example, in a smart home system with multiple devices such as smart bulbs, smart sockets, and smart locks, they need to follow common IoT standards and protocols like Zigbee, Z-Wave, Wi-Fi, Bluetooth, etc., to ensure interoperability and compatibility among them. Similarly, designing an IoT camera device would require measures like data encryption, security authentication and authorization, secure storage, secure transmission, secure updates, etc., to ensure the security of data transmission and storage and to prevent unauthorized access and data leaks.

- Communication and Collaboration: Establishing a good working relationship with customers, maintaining close communication, timely problem-solving, and feedback are essential to meet customer needs and establish long-term partnerships. If customers have specific market demands and launch schedules, suppliers must communicate and agree on specific project progress timelines with the customers and mutually supervise and execute the plan. This is essential to achieve mutual satisfaction and high-quality cooperation.

Through close cooperation and joint efforts between customers and suppliers, the challenges of assembling circuit boards with IoT functionality can be effectively addressed, ensuring the stability, security, and performance of IoT devices, meeting market demands, and enhancing competitiveness.

The development prospects of the Internet of Things (IoT) are extremely broad. With continuous technological advancements and expanding application scenarios, IoT will play a role in more fields, bringing more convenience and innovation to people’s lives. Consequently, there will be an increasing demand for circuit board assembly with IoT functionality. SuperPCBA has over ten years of experience in circuit board assembly, especially in custom PCB assembly, making us highly experienced in this field. We welcome both new and existing customers to contact us for inquiries and orders. Just click on the INQUIRY button in the upper right corner to get in touch and discuss your requirements.