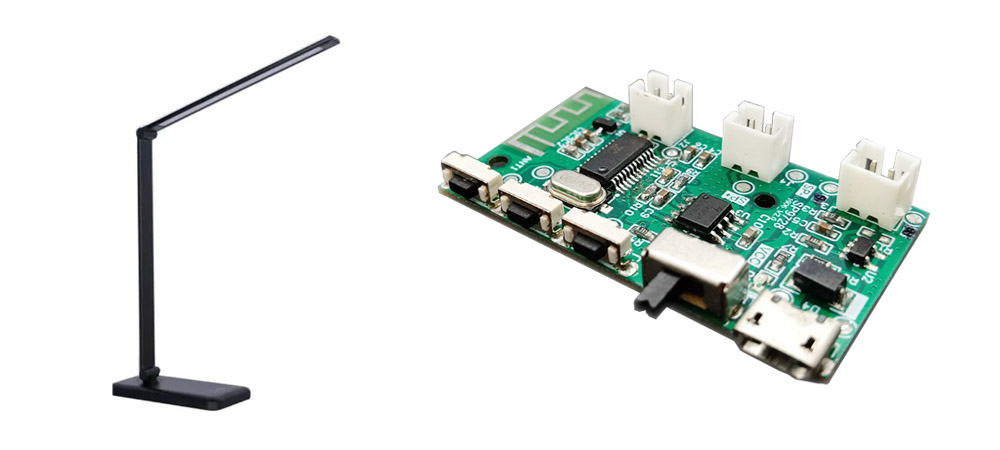

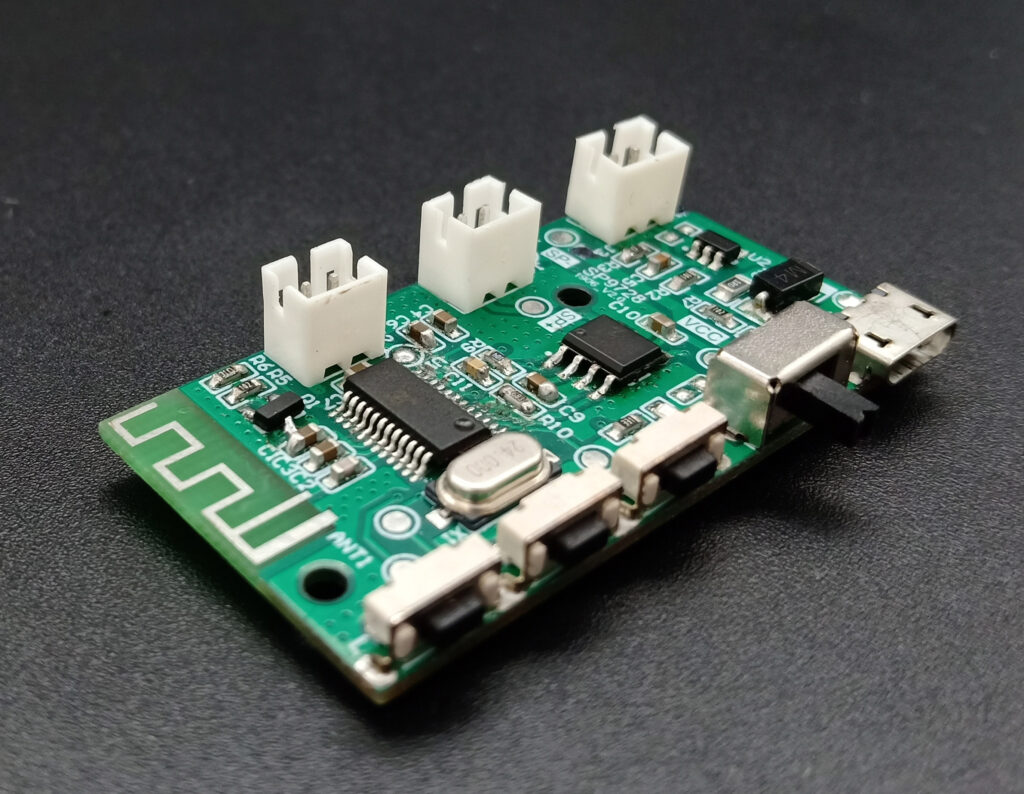

This LED desk lamp is a newly developed LED lighting control board circuit board customized for our American client. It is a tailor-made, flicker-free, and dimmable control board designed specifically for multi-functional desk lamps.

Below are the detailed specifications of this table Lamp Circuit Board Controller:

- Name: Wide Temperature Range Temperature Controller;

- Size: 100*22mm, single-sided board, FR4 (board material can be customized);

- Operating Voltage: DC 9-12V (can be customized for 3.7-24V as needed);

- Features and Advantages:

- LED Soft Light Treatment, Flicker-Free;

- Multi-level Slide Dimming (can define continuous dimming or step dimming);

- Capacitive Touch Sensing;

- Can have multiple touch buttons;

- Touch function can be achieved even when isolated and protected by a medium (such as glass, acrylic, plastic, ceramic, etc.), with excellent anti-interference performance;

- Built-in 3-channel PWM.

- The chip is designed specifically for applications with complex functions and small size, offering multiple design options to meet specific requirements of different customers.

This LED desk lamp control board has undergone customer inspections and has shown excellent performance in stability and safety aspects.

The Importance of Circuit Board Controller Designing for LED Table Lamp

LED table lamps have become increasingly popular and prevalent in the lighting market. Their widespread adoption is due to the numerous advantages offered by LED technology, such as energy efficiency, long lifespan, low heat generation, and the ability to produce customizable lighting effects. A well-designed and reliable circuit board controller is essential to optimize the lamp’s performance, energy efficiency, user experience, and safety, ensuring that LED table lamps continue to meet the demands and preferences of consumers in the lighting market. The importance of a reliable circuit board controller for LED table lamps:

- Smooth Dimming and Color Control: A dependable control board ensures smooth and flicker-free dimming and color temperature adjustment. This feature enhances user comfort and experience, allowing seamless transitions between different brightness levels and color tones.

- Energy Efficiency: An efficient control board design optimizes power usage and minimizes energy wastage. It helps the LED desk lamp deliver high-quality illumination while conserving electricity, which is essential for eco-friendly and cost-effective lighting solutions.

- User Interface: The control board facilitates user interaction with the desk lamp. Intuitive and user-friendly control interfaces, such as touch controls or buttons, improve the overall usability of the lamp.

- Safety and Reliability: A reliable control board design includes safety features such as overcurrent protection, overvoltage protection, and thermal management. These features ensure the LED desk lamp operates safely and reliably, reducing the risk of electrical issues or hazards.

- Compatibility and Connectivity: For smart LED desk lamps, a dependable control board enables seamless integration with smart home systems and various control methods, such as mobile apps and voice commands.

All in all, a well-designed and reliable circuit board controller is essential to optimize the lamp’s performance, energy efficiency, user experience, and safety, ensuring that LED table lamps continue to meet the demands and preferences of consumers in the lighting market.

The Steps to Design A Circuit Board Controller for the LED Table Lamp with Flicker-Free and Continuous Dimming Multi-Key Control

Designing a circuit board controller for an LED table lamp with flicker-free and continuous dimming multi-key control involves the following steps:

- Define Requirements: Clearly outline the lamp’s functional requirements, including flicker-free dimming, continuous dimming, and multi-key control. Determine the power source type (AC or DC) and LED parameters (working voltage, current, etc.).

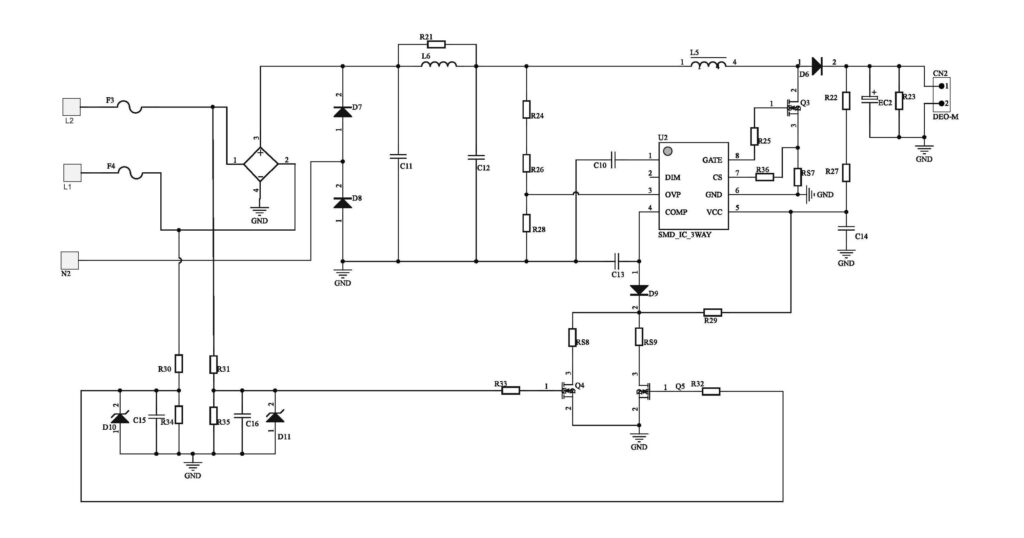

- LED Driver Circuit Design: Design a stable LED driver circuit that supplies a constant current to the LEDs. Ensure the LEDs operate within a safe current range and avoid flickering. High-frequency PWM dimming can be used to achieve flicker-free dimming.

- Multi-key Control: Design the multi-key control interface, typically using buttons or touch switches. Determine the layout of the multi-key control functions, such as dimming, power on/off, and color temperature adjustment.

- Continuous Dimming Design: Continuous dimming requires a continuously adjustable power driver circuit to achieve smooth transitions in LED brightness. This can be accomplished by adjusting the PWM duty cycle.

- Control Circuit Design: Design a suitable control circuit to convert the inputs from the multi-key control interface into corresponding output signals for adjusting LED brightness and other functions.

- Power Management: Consider power management, including overcurrent protection, overvoltage protection, short-circuit protection, and overheat protection, to ensure safe and reliable operation of the LED table lamp.

- PCB Design: Create a PCB (Printed Circuit Board) design to connect all circuits and optimize the layout to reduce electromagnetic interference and enhance stability and reliability.

- Power Source Selection: Choose an appropriate power adapter or driver to ensure a stable power supply.

- Feedback Mechanism: If required, design a feedback mechanism to monitor LED brightness and current for more accurate control.

- Debugging and Testing: After completing the circuit board controller design, perform debugging and testing to ensure the LED table lamp with flicker-free and continuous dimming multi-key control functions as intended and meets user expectations.

So, designing a circuit board controller for an LED table lamp with flicker-free and continuous dimming multi-key control requires careful consideration of LED driver circuits, control interfaces, power management, PCB layout, and functional requirements. The goal is to create an LED table lamp with high performance, safety, reliability, and flicker-free dimming with seamless control through multi-key interfaces.

The Issues Should Be Taken Into Consideration During Designing

When designing a circuit board controller for an LED table lamp with flicker-free and continuous dimming multi-key control, the following issues should be taken into consideration:

- Flicker Issue: To avoid flickering, the control circuit board of the table lamp should use a high-frequency PWM (Pulse Width Modulation) for dimming. A higher PWM frequency will make the dimming process nearly imperceptible, providing a more comfortable lighting experience.

- Continuous Dimming: Achieving continuous dimming requires using a continuously adjustable power drive circuit instead of traditional stepped dimming methods. Continuous dimming allows for smoother brightness adjustments, allowing users to precisely control the light intensity according to their needs.

- Multi-key Control: When designing the control board for the desk lamp, multi-key control functionality should be considered. Multi-key control typically includes dimming buttons, color temperature adjustment buttons, power switches, etc. The layout of the buttons should be arranged logically to ensure convenient and intuitive operation.

- PWM Dimming Stability: The stability of the power supply and circuit is crucial during PWM dimming. It’s essential to ensure a stable voltage and current supply to prevent flickering and unstable brightness. Additionally, the dimming circuit should have appropriate feedback mechanisms to maintain a stable brightness output.

- Electromagnetic Interference: Electromagnetic interference should be considered during the design process to avoid affecting other devices or electronic products. Using appropriate filtering circuits and proper grounding can help reduce electromagnetic interference.

- Thermal Management: The control circuit board of the desk lamp may generate some heat. Ensuring proper thermal management is essential to maintain the normal operation of the circuit board and prolong the lifespan of components. Heat sinks, thermal sensors, and proper routing can assist with heat dissipation.

- Safety and Protection: The desk lamp’s circuit board should be designed with high safety and protection measures. Ensuring the safety of the power switch and other control buttons to avoid direct contact between the circuit board and the user.

- PCB Layout: A well-planned PCB layout can help reduce electromagnetic interference, improve signal integrity, and prevent circuit failures. Attention should be given to separating power and signal lines to avoid interference.

- Testing and Verification: After the design is completed, rigorous testing and verification should be performed to ensure that the control circuit board of the desk lamp meets the design requirements and functions as intended.

In summary, when designing a flicker-free and continuous dimming multi-key control circuit board for an LED table lamp, attention should be given to flicker issues, continuous dimming, multi-key control, PWM dimming stability, electromagnetic interference, thermal management, safety and protection, PCB layout, testing, and verification. This will ensure the performance and stability of the table lamp.

The Key Points Should Be Taken Into Consideration During Production

With the development of modern electronic technology, the size of PCBA components has become smaller, and the density has increased. The spacing between components and the height of component placement above the PCB (distance from the PCB to the ground) have also reduced. Environmental factors have a greater impact on PCBA, leading SuperPCBA to place higher demands on the reliability of electronic products’ PCBA.

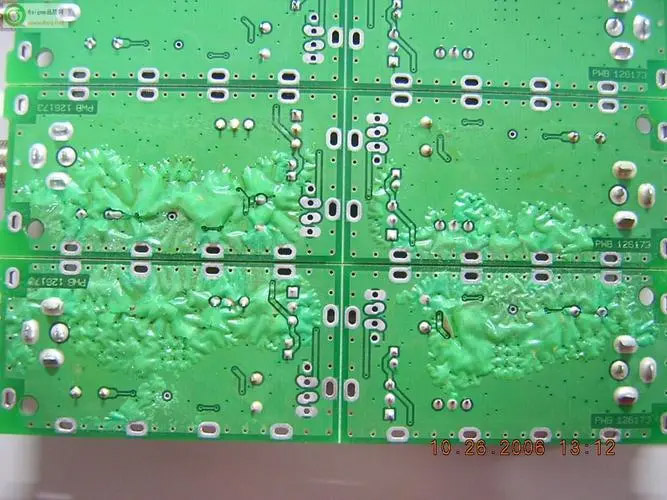

- Firstly, there is the issue of board surface bubbling. The most common problem during the production of circuit boards is board surface bubbling. Why does board surface bubbling occur? The reasons are mainly threefold. Firstly, poor adhesion caused by the cleanliness and microscopic roughness of the board surface, making it difficult to resist the stress generated during subsequent production and assembly processes, such as plating stress, mechanical stress, and thermal stress, ultimately leading to varying degrees of separation between the plating layers. Secondly, if the copper-clad board oxidizes in the air, it may not only lead to the lack of copper in holes and a rough board surface but also cause board surface bubbling. Thirdly, if the copper-clad board is stored in acid for too long, it may also oxidize, resulting in board surface bubbling.

- Secondly, there is the design of circuit board printing. Sometimes, even if the circuit schematic design is correct, improper printed circuit board (PCB) design can also negatively impact the reliability of electronic devices. For example, if two fine parallel lines on the printed board are close together, it will create waveform delay and generate reflection noise at the transmission line terminal. Poor consideration of power and ground lines can also cause interference and degrade product performance. Therefore, when designing printed circuit boards, it is essential to use the correct methods.

- Lastly, there is the risk of corrosion. Electronic PCB components exposed to the external environment are almost always at risk of corrosion, with water being the main medium. Water molecules are small enough to penetrate the molecular gaps of certain polymer materials and reach the underlying metal, causing corrosion. When the atmosphere reaches a certain humidity level, it can trigger PCB electrochemical migration, leakage current, and distortion in high-frequency circuits. Therefore, moisture resistance is an essential aspect of protecting products.

In conclusion, the challenges in PCBA assembly include board surface bubbling, PCB design considerations, and the risk of corrosion. To ensure the reliability of electronic products, attention must be given to these issues during the design and production process.

SuperPCBA has many years of experience in control board design and production, making the LED touch dimmable desk lamp control PCB a product with a significant advantage. Not only is the quality very stable, but the cost is also well-controlled. New and existing customers in need, please do not hesitate to click the INQUIRY button to contact us!