LED PCBs are Printed Circuit Boards specifically designed to support Light Emitting Diodes (LEDs). These PCBs are designed to accommodate the specific requirements of LED lighting, including heat dissipation, thermal management, and electrical connectivity. LED PCBs come in various shapes and sizes, depending on the application, and are typically made of materials that provide better heat dissipation, such as aluminum or copper. The design of LED PCBs can vary depending on the application, with some featuring a single LED and others having multiple LEDs.

The base material of LED PCBs is typically made of aluminum or copper. Aluminum is commonly used because it has good thermal conductivity and is lightweight, which helps dissipate heat generated by the LED. Copper is also a good option for LED PCBs because it has even higher thermal conductivity than aluminum, but it is heavier and more expensive. The base material is coated with a layer of dielectric material such as polyimide, which provides insulation and electrical properties. The top layer of the LED PCB is made of copper, which serves as the conductive layer for electrical connections.

Compared to traditional lighting, LED lighting using LED PCBs offers several advantages:

Energy efficiency: LED lighting is much more energy-efficient than traditional lighting, consuming significantly less power for the same amount of light output.

Longer lifespan: LEDs have a much longer lifespan than traditional lighting, lasting up to 50,000 hours or more. This means less frequent replacements and maintenance.

Greater flexibility: LED PCBs can be designed in various shapes and sizes to fit a wide range of lighting applications.

Higher brightness: LEDs can produce a higher brightness than traditional lighting, making them suitable for a range of applications where high-intensity lighting is required.

Lower heat dissipation: LEDs generate less heat than traditional lighting, reducing the need for cooling systems and allowing for better control over the operating temperature.

Overall, the use of LED PCBs for lighting offers a more efficient, longer-lasting, and flexible solution than traditional lighting.

LED PCBs have a wide range of applications, including:

Lighting: LED PCBs are commonly used in lighting fixtures, such as LED bulbs, downlights, and streetlights.

Automotive industry: LED PCBs are used in automotive lighting, including headlights, tail lights, and interior lighting.

Displays: LED PCBs are used in various types of displays, including indoor and outdoor signage, scoreboards, and electronic billboards.

Consumer electronics: LED PCBs are used in various consumer electronic devices, including televisions, computer monitors, and mobile phones.

Medical devices: LED PCBs are used in medical devices such as surgical lighting, diagnostic equipment, and medical imaging equipment.

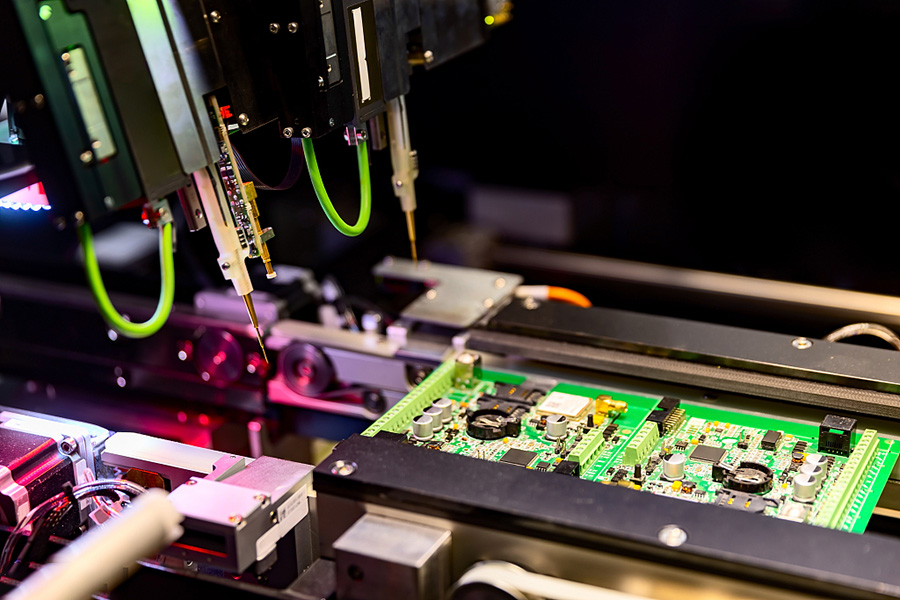

Industrial applications: LED PCBs are used in industrial applications such as machine vision systems, sensors, and automation equipment.

Overall, LED PCBs are versatile and can be found in many different applications due to their high efficiency, low power consumption, and long lifespan.

Get a factory directly price quote with 24 hours.

Pls input your email address correctly!

Make sure your name and email is right.