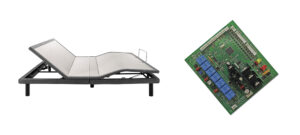

In today’s rapidly advancing smart home technology landscape, electric beds have become increasingly popular in modern households due to their exceptional comfort and convenience. At the core of these beds lies the control board, responsible for enabling a variety of intelligent features and ensuring an optimal user experience. Drawing from our collaboration with European clients on intelligent electric bed control boards, this article explores the technical implementation, functional realization, cost control, and safety certifications relevant to these control boards. Designing an electric bed control board involves intricate circuit and software development while also considering cost-effectiveness and safety standards. Let’s first examine the essential features a market-ready electric bed should possess.

Features

With the control board, an intelligent electric bed can offer the following functionalities:

- Lift Function: Independent adjustment settings for the back and foot areas.

- Preset Mode Buttons: Zero-gravity mode, TV mode, computer mode, and leisure mode.

- One-Touch Flat: Quickly return the bed to a flat position.

- USB Charging: Convenient charging ports.

- Wall Hugger: Ensures the bed stays close to the wall when adjusting.

- Vibration Massage: Three levels of massage intensity.

- Bed Frame Design: Thoughtful structural design.

- App Control/Alarm/TV Mode: Seamless control through a mobile app.

These features represent the fundamental capabilities of an intelligent electric bed, which can be adjusted or modified based on client requirements. All these features are controlled and realized through the control board.

Technical Implementation

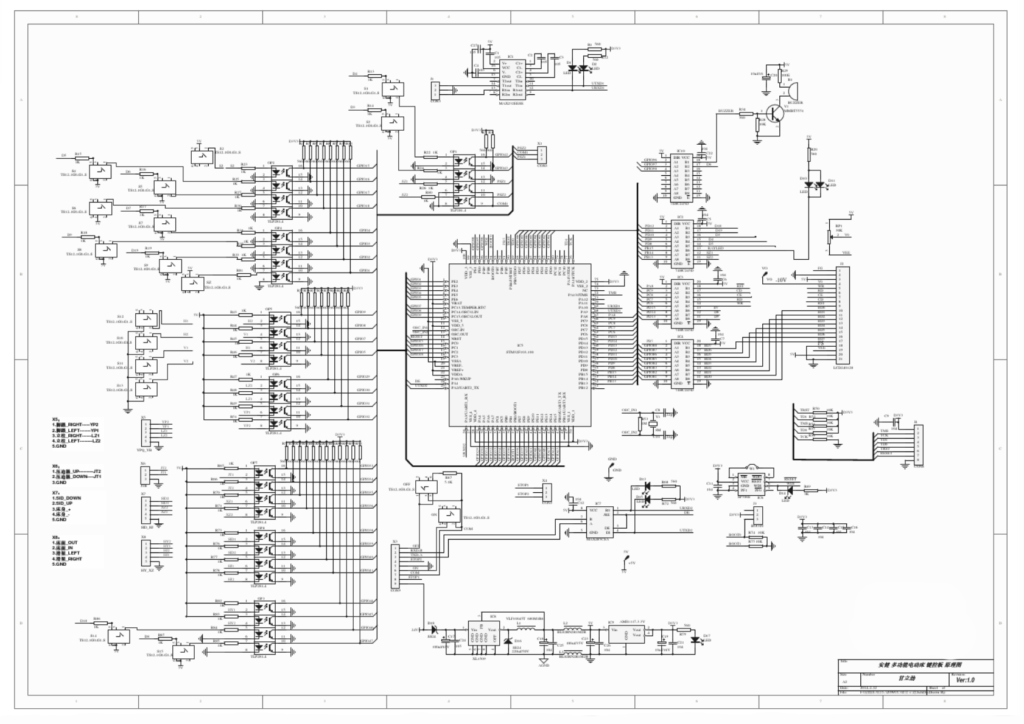

To design a control board that meets market demands, several key technologies are required:

- Circuit Design: Create a robust circuit schematic and PCB layout to ensure signal integrity and power stability.

- Firmware Development: Write efficient control programs to ensure stable functionality and responsive performance.

- Debugging and Testing: Conduct thorough debugging and testing to identify and resolve potential issues, ensuring product reliability.

Functional Realization

In implementing the various functions of the control board, specific considerations are necessary for each feature:

- Lift Function

- Motor Selection and Control: Choose appropriate motors and drivers to achieve independent adjustment for the back and foot areas, ensuring sufficient power with minimal noise.

- Position Sensors: Use position sensors (e.g., Hall effect sensors or optical sensors) to accurately detect and control the lift position.

- Preset Mode Buttons

- Store Preset Positions: Use EEPROM or other non-volatile memory to save different preset positions, ensuring they are retained after power loss.

- User Interface Design: Ensure the button layout is logical and easy to operate, with clear indicators or displays.

- One-Touch Flat

- Quick Response: Ensure the bed quickly and smoothly returns to a flat position when the button is pressed.

- Safety Mechanisms: Design appropriate safety mechanisms to prevent harm to the user during the flattening process.

- USB Charging

- Power Management: Ensure the USB port provides stable voltage and current without affecting other functions during bed operation.

- Overload Protection: Design overload protection to prevent damage to the control board from overcurrent or short circuits.

- Wall Hugger

- Space Management: Ensure the bed maintains a suitable distance from the wall during adjustments to avoid friction or collisions.

- Vibration Massage

- Motor Control: Choose suitable vibration motors with adequate intensity and durability.

- Level Adjustment: Design an appropriate control circuit to adjust the vibration intensity.

- Bed Frame Design

- Structural Design: Ensure the control board is securely installed and connected to the bed frame, without being affected by external forces during use.

- Heat Dissipation: Consider heat dissipation to ensure the control board remains stable during long-term operation.

- App Control/Alarm/TV Mode

- Wireless Communication: Use reliable wireless communication technologies (e.g., Wi-Fi, Bluetooth) to connect with a mobile app.

- Software Development: Develop a user-friendly app to ensure easy operation and intuitive interface.

- Synchronization: Ensure the alarm and TV modes synchronize with the actual device to provide accurate time and control.

Cost Control

Designing the control board also involves managing costs while meeting product functionality:

- Component Selection: Choose cost-effective components that meet performance requirements.

- Manufacturing Process: Select appropriate manufacturing processes to optimize production flow and reduce unnecessary costs.

Safety and Certification

Any product must meet safety certifications to be market-ready. The following are critical safety and certification considerations for the electric bed control board:

- Electrical Safety: Ensure the control board design complies with relevant electrical safety standards to prevent risks such as leakage and short circuits.

- Electromagnetic Compatibility: Ensure the control board does not interfere with other electronic devices and is resistant to interference.

- Certification and Testing: Obtain necessary product certifications and conduct testing (e.g., CE, FCC) to ensure market compliance.

Conclusion

We hope this article provides you with a comprehensive understanding of the design technology, functional realization, cost control, and safety certifications of intelligent electric bed control boards. High-quality control board design is key to ensuring product performance and user satisfaction. SuperPCBA is committed to delivering high-quality electronic manufacturing solutions, backed by extensive experience and a professional technical team, to meet your diverse needs. If you have any questions or requirements regarding intelligent electric bed control boards or other control board manufacturing, we invite you to contact us at sales@superpcba.com. We look forward to collaborating with you to create high-quality smart home products, offering your customers a more comfortable and convenient living experience.