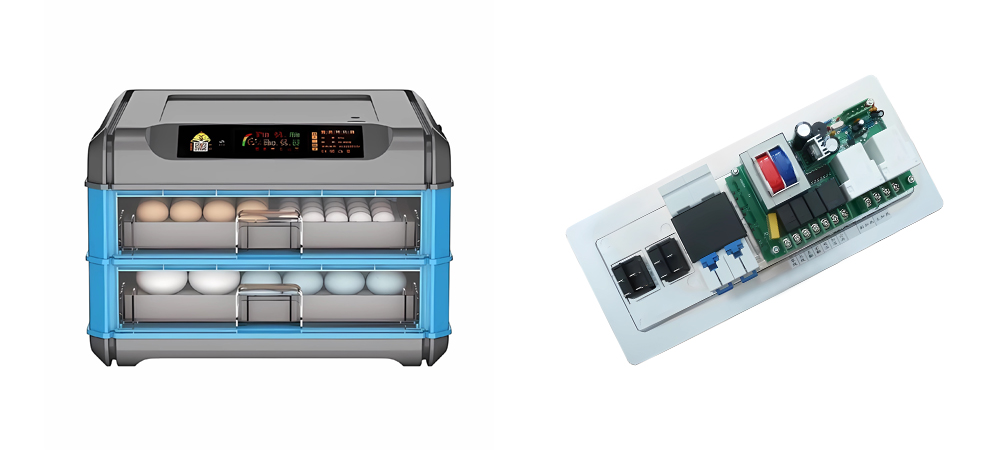

Project Introduction

The control board of this incubator is designed and manufactured for a new type of household automatic incubator for our American client. The temperature control and humidity control are highly sensitive and accurate. It enables automatic egg turning, alarm functions, and ventilation. Moreover, the egg turning cycle and time can be customized according to the client’s needs. The ventilation cycle and time can also be adjusted to meet the incubation requirements of end customers. It can fulfill the incubation needs of various types of eggs for the majority of customers. The functionality and precision of the control board can be further fine-tuned according to the client’s requirements.

Product Function

- Temperature display range: 10 to 55℃

- Temperature measurement accuracy: ±0.1℃

- Humidity display range: 0 to 99%

- Humidity control accuracy: ±5%

- Number of outputs: 8 channels (over-temperature, temperature control, low temperature, left egg turning, right egg turning, humidity control, alarm, ventilation)

- Output current: Temperature control and low temperature: 10A, others: 1A

- Egg turning count: Maximum record of 999 times.

- Egg turning cycle: Adjustable from 10 minutes to 10 hours (factory default: 1.5 hours)

- Egg turning time: Adjustable from 1 to 300 seconds (factory default: 180 seconds)

- Ventilation cycle: Adjustable from 5 to 999 minutes (factory default: 2 hours)

- Ventilation time: Adjustable from 0 to 999 seconds (factory default: 30 seconds)

- Measurement wire length: Approximately 1.6 meters.

The controller circuit board is important for the incubators.

Designing a qualified control board for an incubator is crucial for the following reasons:

- Temperature Control: Temperature is a critical factor during the incubation process. A qualified control board can accurately monitor and control the temperature inside the incubator, ensuring it remains within the appropriate range for successful hatching.

- Humidity Control: In addition to temperature, humidity also plays a vital role in incubation. The control board should be able to monitor and regulate the humidity levels inside the incubator, ensuring the environment maintains suitable humidity for successful egg hatching.

- Time Control: A qualified control board possesses precise time control functionality, accurately timing different stages of incubation, such as the incubation period, egg turning period, and hatching completion, to provide the appropriate environment and conditions.

- Safety and Reliability: The design of the control board should comply with relevant safety standards, ensuring there are no safety hazards during operation. A qualified control board should also offer reliability to ensure stability and consistent performance during long-term operation.

- User Interface and User-Friendliness: The control board should have an intuitive user interface and easy-to-operate functions, allowing users to easily set and adjust parameters. Clear displays and a simple operating interface enhance the user experience.

- Customizability: A qualified control board should also offer a certain level of customization to meet the diverse needs of users. For example, adjustable temperature and humidity ranges, programmable incubation cycles, and alarm functions.

In conclusion, a qualified control board is crucial for the performance and operation of an incubator. It ensures stability and accuracy in the incubation environment, provides optimal conditions for hatching success, and offers users a convenient experience.

You need to pay attention to below key points when you want to make sure your controller circuit boards for incubator could meet your required functionality.

- Determine Requirements and Functional Specifications: Clearly define the requirements and functional specifications of the incubator, including temperature range, humidity range, time control, alarm system, etc. Ensure that the control board can meet these requirements.

- Select Suitable Sensors and Actuators: Choose appropriate temperature sensors, humidity sensors, and actuators to accurately monitor and control temperature and humidity. These sensors and actuators should have high precision and reliability.

- Choose Appropriate Control Algorithms: Based on the requirements and functional specifications, select suitable control algorithms to achieve precise control of temperature and humidity. This may include PID control, feedback control, or other appropriate algorithms.

- Consider Safety: Ensure that the design of the control board meets relevant safety standards to eliminate safety hazards during operation. Implement necessary safety measures such as over-temperature protection, electrical isolation, etc.

- Provide User-Friendly Interface: Design a user-friendly interface that allows users to easily operate and adjust the control board. This can include a clear display screen, understandable menus, intuitive buttons, etc.

- Perform Reliability Testing: Conduct rigorous reliability testing before production, including long-term operation testing, stability testing of temperature and humidity, etc., to ensure the stability and consistency of the control board under different environments and conditions.

- Compatibility with Other Components: Ensure compatibility between the control board and other components of the incubator (such as heaters, fans, etc.) to ensure their coordinated operation.

- Optimize Energy Efficiency and Energy-saving Features: Consider energy efficiency and energy-saving features in the design of the control board to minimize energy consumption while meeting incubation requirements.

These are key aspects to consider when designing and manufacturing a control board for an incubator. Throughout the process, collaboration with relevant professionals (such as electronic engineers, control engineers, etc.) and conducting appropriate testing and validation are essential to ensure the functionality and performance of the circuit board meet the expected requirements.

We SuperPCBA has experienced electronic engineers, control engineers who can help you with your incubator controller circuit boards. And it could lower down your purchasing budget a lot if you purchase the circuit boards yourself for your incubator projects. Further more, it’s better for the quality control to meet your expected requirements of incubators. Now, contact us for a good price and delivery time!