As an engineer at SuperPCBA, I am honored to introduce this article on how to shield control boards from EMI (Electromagnetic Interference). In modern electronic product design, EMI is a significant issue that cannot be ignored. EMI not only affects the normal operation of electronic devices but can also adversely affect other devices and systems. Therefore, effectively shielding EMI during the design and production of control boards becomes a key topic. This article will explore the definition of EMI, its impact on control boards, and share experiences and methods for considering and solving EMI shielding issues during the design and production phases.

By thoroughly understanding EMI and its impact, you can better optimize control board design to ensure the stability and reliability of electronic products. Whether selecting materials, designing layouts, or taking effective shielding measures during production, we will provide comprehensive guidance and suggestions.

What is EMI?

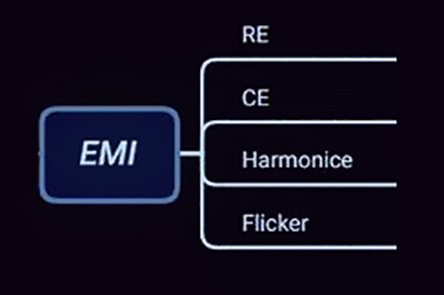

Definition Electromagnetic Interference (EMI) refers to the adverse effects of electromagnetic waves on electronic devices, systems, or communication signals. EMI can come from natural phenomena (such as lightning, solar storms) or man-made devices (such as motors, transformers, radio transmitters, computers, etc.). This interference can affect the normal functioning of equipment, causing signal distortion, data loss, and even damage to the devices.

Moreover, the issue of EMI is becoming increasingly severe due to the increase in electronic devices, the application of high-frequency circuits, the development of high-density integrated circuits, the complexity of power design, and the increasingly complex electromagnetic environment.

In summary, the impact of EMI on control boards can be outlined as follows:

- Signal Distortion and Data Errors: EMI may cause signal distortion, leading to errors in data transmission, affecting the accuracy of communication and data processing.

- Decreased Device Performance: Interference signals can affect the working performance of the circuit board, leading to unstable operation or reduced efficiency of the equipment.

- Functional Failure: Strong EMI interference may cause certain functions on the circuit board to fail, such as inaccurate sensor readings or control commands not being executed.

- Hardware Damage: Prolonged exposure to strong EMI environments may damage sensitive components on the circuit board, shortening the lifespan of the equipment.

How to Shield EMI

Although EMI can impact the functionality of control boards, not all control boards require EMI shielding. This mainly depends on the different functions of the control boards. Reasonably managing EMI operations on control boards can ensure the performance of the circuit board while optimizing cost control.

Which control boards need EMI shielding? Whether a control board requires EMI shielding depends on the specific application environment and equipment requirements. Here are some considerations:

- High-Frequency Circuits: High-frequency circuits (such as RF communication, microwave devices) are prone to electromagnetic interference and require EMI shielding to ensure signal integrity.

- Sensitive Equipment: Some equipment sensitive to electromagnetic interference (such as medical devices, precision instruments) requires strict EMI shielding measures to ensure normal operation and safety.

- Complex Electromagnetic Environments: Equipment working in complex electromagnetic environments, such as industrial control systems and automotive electronic systems, need EMI shielding to avoid external interference.

- Strict Regulatory Requirements: Some industries and countries have stringent regulations on electromagnetic compatibility (EMC) requiring EMI shielding for control boards to meet compliance standards.

- Communication Equipment: For wireless communication devices or data transmission systems, EMI shielding helps improve signal transmission quality and reliability.

Knowing which control boards need EMI shielding, factories must effectively manage and shield these control boards’ EMI during the design and production process. Here are some considerations for addressing this issue:

Design Phase

- Reasonable PCB Layout

- Signal Integrity: Avoid long, unshielded signal paths to reduce radiation and crosstalk.

- Separate High and Low-Frequency Circuits: Arrange high-frequency and low-frequency circuits separately to reduce mutual interference.

- Ground Plane Design: Use continuous ground planes to reduce electromagnetic radiation and improve signal integrity.

- Wiring Layers and Shielding Layers: Add shielding layers above and below key signal paths to reduce EMI.

- Selection of Appropriate Components

- Low-Noise Components: Choose low-noise components and device packages to reduce EMI.

- Shielded Components: Use components with built-in shielding, such as shielded inductors and connectors.

- Filter Design

- Power Filtering: Use filter capacitors and inductors at the power input and on sensitive circuits to reduce electromagnetic interference.

- Signal Filtering: Add filter circuits to key signal paths to reduce high-frequency noise.

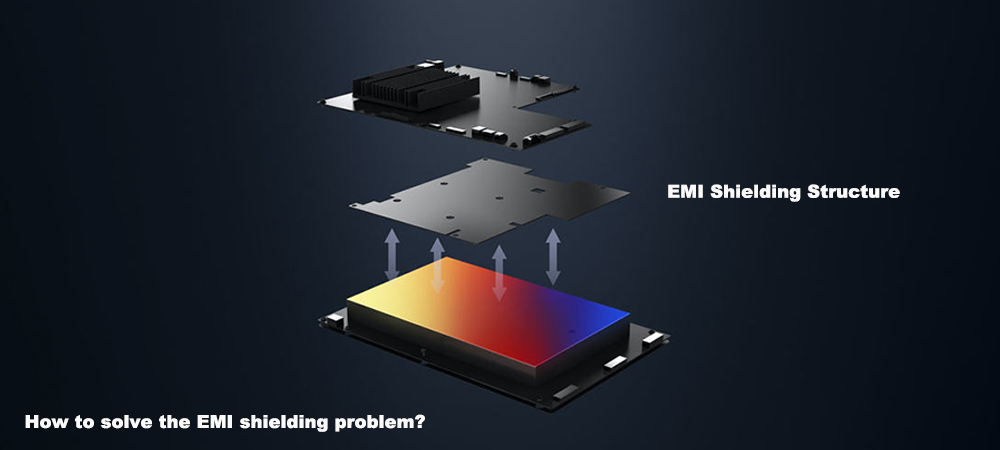

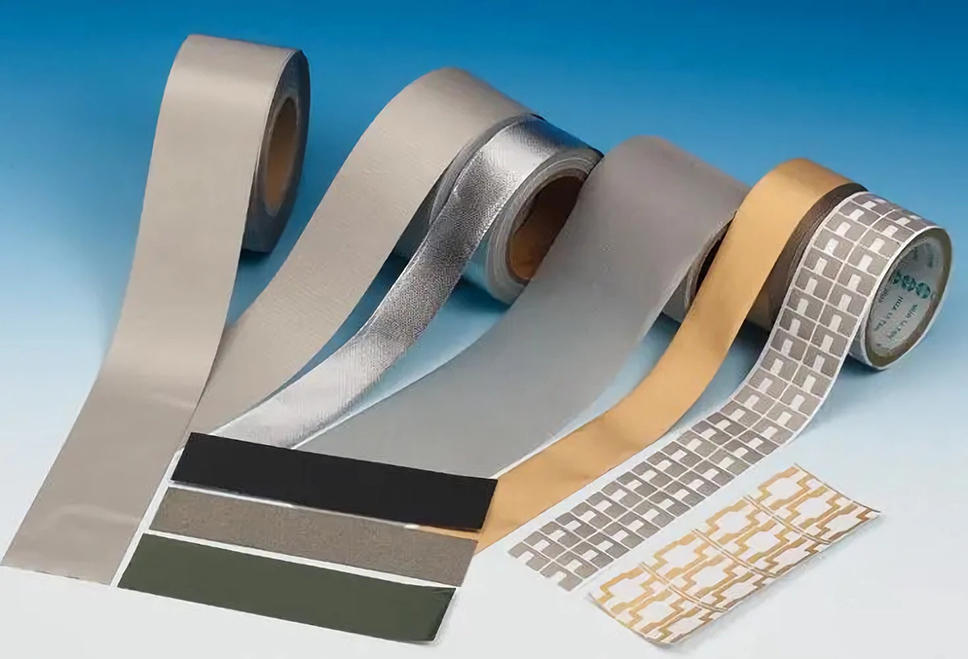

- Selection of Shielding Materials

- Shielding Enclosures: Use metal shielding enclosures in critical circuit areas.

- Shielding Films: Add EMI shielding films between PCB layers to improve overall shielding effectiveness.

- PCB Layer Stack Design

- Multi-Layer Design: Utilize multi-layer PCB design to add power and ground planes, reducing electromagnetic interference.

Production Phase

- Manufacturing Precision

- High-Precision Manufacturing: Ensure high precision in the PCB manufacturing process to avoid EMI issues due to manufacturing defects.

- Strict Process Control: Maintain strict process control during manufacturing to ensure correct installation of shielding materials and filtering components.

- Application of EMI Shielding

- Application of Shielding Films: Accurately apply EMI shielding films during production to ensure proper adhesion to the PCB.

- Installation of Shielding Enclosures: Ensure proper contact between shielding enclosures and the PCB, and connection to the ground.

- Testing and Verification

- EMI Testing: Conduct EMI testing during production and before product shipment to ensure compliance with relevant electromagnetic compatibility standards.

- Environmental Simulation: Simulate the working conditions of the product in actual usage environments for EMI testing and verification.

- Quality Control

- Production Process Monitoring: Monitor the production process to ensure all shielding measures and design requirements are strictly implemented.

- Regular Calibration and Testing: Regularly calibrate and test production equipment to ensure its stability and accuracy.

Conclusion

We hope this detailed discussion helps you gain a deeper understanding of EMI and its impact on control boards, and grasp effective methods and techniques for EMI shielding during the design and production phases. Effective EMI shielding not only improves the performance and reliability of control boards but also ensures compliance and market competitiveness of electronic products. SuperPCBA is dedicated to providing professional electronic manufacturing solutions, with rich experience and advanced technology to help you solve various EMI shielding challenges.

If you have any questions or needs regarding control board EMI shielding or other electronic manufacturing aspects, we sincerely invite you to contact us at sales@superpcba.com. Our professional team will provide you with high-quality services and customized solutions to help your products stand out in the market.