The control panel of this fully automatic coffee grinder was developed and prototyped by our company, SuperPCBA, in collaboration with a German client, according to their requirements. This control panel enables the following functionalities for the coffee machine:

- 5-level adjustable cup size,

- High-value ceramic grinding unit ceramDrive,

- Individually adjustable beverage temperature,

- Innovative heating system,

- Coffee variety: Espresso, Espresso Macchiato, Coffee, Cappuccino, Latte Macchiato, Caffe Latte,

- autoMilk Clean: automatically cleans the milk system.

Below, we’d like to share the steps required to design a control panel for such a fully automatic multi-functional coffee machine, the selection of key components, and considerations for collaborating with Chinese suppliers.

Steps Required for Designing a Coffee Machine Control Panel:

Designing the control panel for a coffee machine involves several essential steps. First, you need to understand the basic construction of the coffee machine. Then, considering the specific requirements of your client, you must think about factors like the coffee machine’s functions, performance, cost, and reliability.

- Define Functional Requirements: Before designing the coffee machine control panel, it’s crucial to outline the functionality and performance requirements of the circuit. This encompasses aspects like control methods, heating modes, temperature control ranges, brewing time, and pressure.

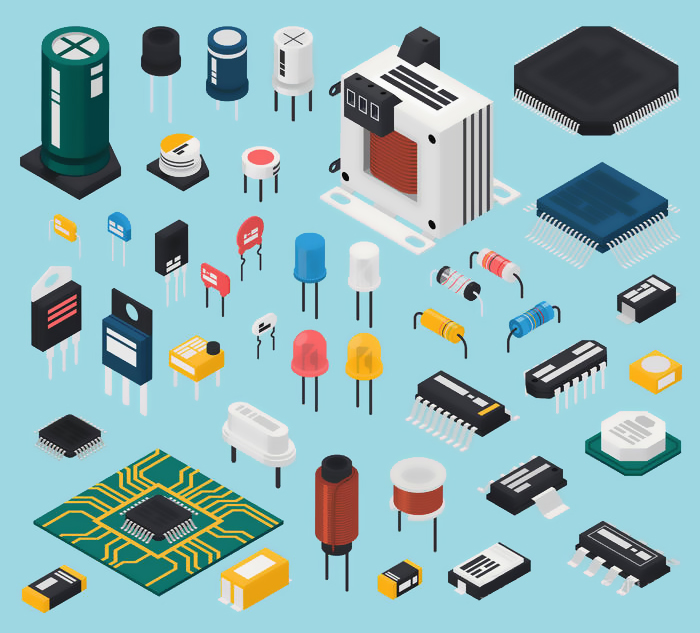

- Select Appropriate Electronic Components: Based on the requirements, choose suitable electronic components such as thyristors, relays, transistors, resistors, capacitors, and more. When selecting components, consider specifications, voltage tolerance, current ratings, safety aspects, and reliability.

- Design the Control Circuit: Using the chosen electronic components and the defined requirements, design the control circuit. This involves switch controls, power controls, temperature controls, and more. Stability, response speed, circuit protection, and safety measures are crucial considerations for the control panel.

- Plan the Output Circuit: Design the output circuit based on the output signals from the control circuit. This includes motor control circuits, heating element control circuits, temperature sensor control circuits, etc. Like the control circuit, stability, precision, circuit protection, and safety measures are vital for the output circuit.

- Test the Circuit: Thoroughly test the designed coffee machine circuit to ensure it meets the required functionality and performance standards. Testing involves assessing stability, response speed, circuit protection, and safety measures.

- Optimize the control panel: Based on the test results, optimize the circuit to enhance its performance and stability. Optimization might involve adjusting the circuit layout, connections, and component choices.

- Create Samples: Once the control panel design is complete, create samples to validate the circuit’s performance and stability. Sample production should account for accuracy, reliability, circuit protection, and safety measures.

These steps, when followed meticulously, ensure the successful design of a coffee machine control panel that meets the desired functionality, reliability, and safety standards.

Recommended Core Components:

The specific component selection will depend on factors such as your coffee machine’s functionality, performance requirements, and budget. Here are some commonly used and cost-effective component brands for control panel design. You can choose based on your actual needs:

Microprocessors/Microcontrollers:

- Texas Instruments

- NXP

- STMicroelectronics

Communication Modules:

- Siemens

- Quectel

- Seagate

Sensors:

- Bosch Sensortec

- Honeywell

- Maxim Integrated

Displays:

- LG Display

- BenQ

- Hitachi

Power Management Chips:

- MaxLinear

- Analog Devices

- ON Semiconductor

Communication Interface Chips:

- Renesas Electronics

- Texas Instruments

- STMicroelectronics

Protection Components:

- Panasonic

- ROHM Semiconductor

- Littelfuse

Temperature Sensors:

- Texas Instruments

- Sensirion

- Maxim Integrated

Security Chips:

- Texas Instruments

- Infineon

- MaxLinear

Please note that the component landscape is continuously evolving due to technological advancements. When selecting components, it’s advisable to conduct market research to explore the latest products and technologies from various brands. This ensures your design benefits from the latest performance and reliability. Additionally, based on your design requirements, you can also communicate with component suppliers or distributors for more specific recommendations.

Considerations When Choosing Chinese Suppliers:

Given the market price and control board cost considerations, you may opt to have the control panel produced by a Chinese supplier such as Ningbo SuperPCBA Manufacture Co., Ltd. Here are some points to keep in mind while collaborating with Chinese suppliers:

- Partner Selection: Choose reputable and experienced suppliers, conduct thorough investigations and background checks to ensure they possess production capabilities and quality assurance.

- Intellectual Property Protection: Clearly define intellectual property ownership and protection measures in the cooperation agreement to prevent misuse of your design and technology.

- Technical Specifications: Provide detailed technical specifications and documents, including schematics, PCB design, Bill of Materials (BOM), production drawings, etc., to ensure the supplier accurately understands and produces your control board.

- Sample Validation: Prior to full-scale production, create a batch of samples for validation. Ensure the samples align with your design and meet your quality and performance standards.

- Supply Chain Management: Monitor every link in the supply chain to ensure necessary components are supplied on time, thus avoiding production delays.

- Production Process and Quality Inspection: Ensure the supplier has a comprehensive production process and quality inspection procedures in place to guarantee product quality and stability.

- Quality Standards and Certifications: Ensure the supplier adheres to your quality standards and requirements and holds necessary certifications like ISO certification.

- Delivery Time: Ensure the supplier can produce and deliver according to your specified delivery timeline to avoid impacting your market launch plans.

- Communication and Feedback: Establish effective communication channels with the supplier for timely issue resolution and addressing needs, ensuring smooth cooperation.

- Legal and Compliance: Ensure that the cooperation agreement and contract cover terms related to legal and compliance aspects, safeguarding the interests of both parties.

- After-Sales Support: Ensure the supplier provides necessary after-sales support, including repair and replacement services within the warranty period.

- Cost Management: Ensure the cost budget is reasonable while also being mindful not to compromise product quality and performance by cutting costs.

Taking all these factors into consideration and building a strong working relationship with the supplier, detailed planning, and effective communication will aid in ensuring the smooth and high-quality completion of your control board production process in China.

Conclusion:

It’s worth noting that designing a coffee machine control panel involves considering a multitude of factors, including circuit functionality, performance, cost, and reliability, among others. Therefore, prior to coffee machine control panel design, thorough market research and technical analysis are essential to ensure that the circuit’s design aligns with market demands and technological trends. At SuperPCBA, we have over 10 years of experience in custom circuit board control board solutions and have successfully completed control board projects for over 200 different products in collaboration with clients from various countries. Upholding the principle of co-creating brilliance with our clients, we strive to offer the most reasonable cost, top-quality service, and swift communication. We welcome both new and existing clients to reach out for inquiries and discussions. Feel free to click the INQUIRY button at the top right corner to get in touch with us!