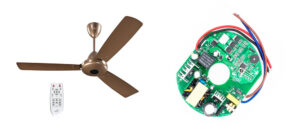

The control board for this brushless motor fan was designed and developed by us in collaboration with an Indian client. India is well-known as one of the largest fan markets in the world and a significant producer of fans. Consequently, the fan market in India is highly competitive. Due to the large market size, numerous brands offer fan products across different price ranges to cater to the diverse needs of consumers. Price is a crucial factor in the Indian fan market, as consumers are price-sensitive and choose products based on their budget. This control board for the brushless motor fan takes into consideration the end customers’ requirements for energy efficiency, reduced fan noise, stepless speed control, and safety. Through optimization by our engineers, we have effectively controlled the production costs, resulting in a 16% reduction in the client’s purchasing budget. Now, let’s explore the key points to consider when designing and producing a control board for a brushless motor ceiling fan!

The Application of BLDC in Ceiling Fan

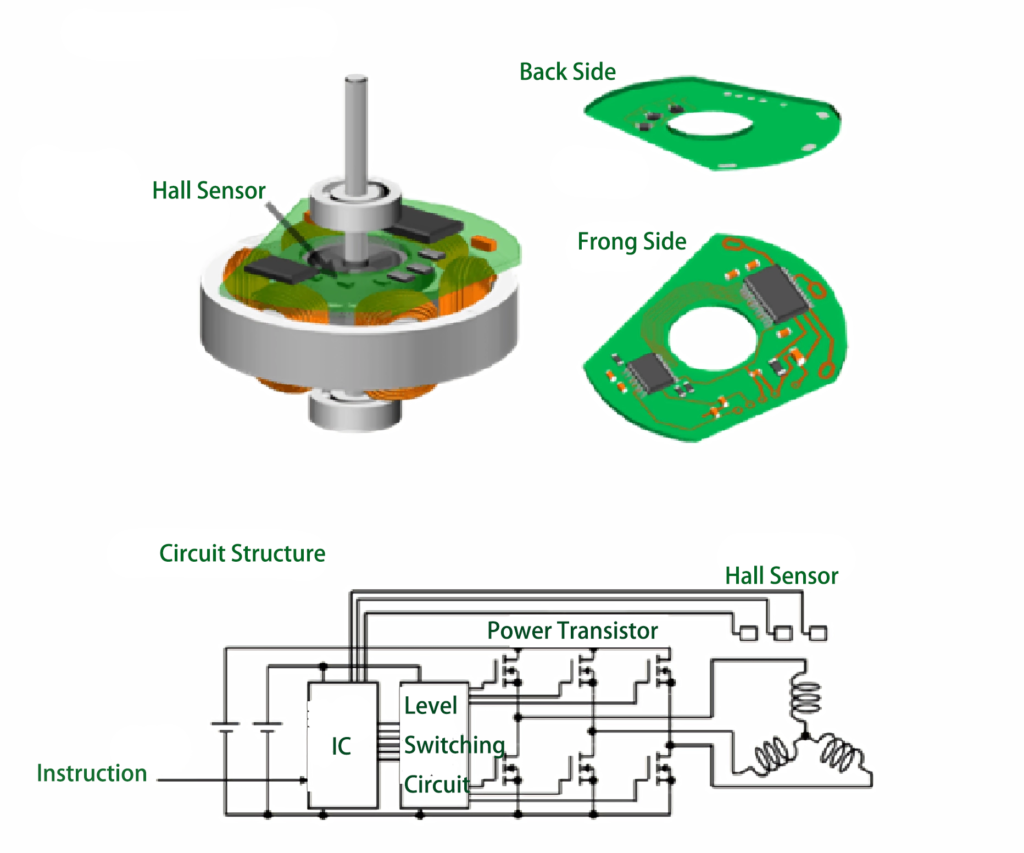

A brushless DC motor is an electric motor that offers higher efficiency and reliability compared to traditional brushed DC motors. Unlike brushed DC motors that use mechanical brushes to control the current flow, brushless DC motors utilize an electronic control system for current control.

Brushless motors have found wide applications in the fan industry and have achieved significant accomplishments and market recognition.

The Advantage of BLDC Ceiling Fan

- High Efficiency and Energy Saving: Compared to traditional induction motors, brushless motors have higher energy utilization efficiency. They can provide the same air power or air volume with lower energy consumption, achieving high efficiency and energy-saving effects.

- Variable Speed Control: Brushless motors have precise speed control capabilities. By adjusting the current and voltage, multi-speed control for ceiling fans can be achieved to meet different needs and scenarios.

- Smooth Operation: Brushless motors operate more smoothly with minimal torque fluctuations. Compared to traditional electric motors, brushless motors run quieter, reducing noise and vibration.

- Longevity and Reliability: Due to the absence of brushes, brushless motors eliminate issues caused by brush wear and friction, thereby improving motor longevity and reliability. Brushless motors typically use permanent magnets as rotors, resulting in lower mechanical wear and increased durability.

- Smart and Remote Control: The application of brushless motors also promotes the smartization of ceiling fans. By integrating with smart home systems, remote control, timer switches, and speed adjustments can be achieved, providing a more convenient user experience.

- Design Diversity: The miniaturization and compact design of brushless motors enable greater diversity in the appearance of ceiling fans. Manufacturers can flexibly design the shape, blade material, and aesthetic style of ceiling fans to meet consumers’ personalized demands for fan appearance.

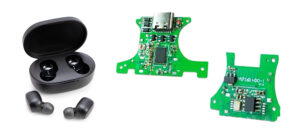

How to design a circuit board for a BLDC ceiling?

Circuit board design is a complex process that involves careful consideration of the following steps:

- Determine Requirements and Specifications: Clearly define the functional requirements and specification of the ceiling fan circuit board. This includes the motor power requirements, speed control range, input voltage and current, interface requirements, etc.

- Select Motor Driver: Choose an appropriate motor driver circuit based on the motor specifications. Ensure that the motor driver can provide the required power output, speed control functionality, and necessary protection features.

- Create Circuit Schematic: Draw the circuit schematic based on the selected motor driver and other electronic components. Ensure proper connections of the driver, power management circuit, signal interfaces, and protection circuitry.

- Select Suitable Components: Choose suitable electronic components based on the circuit schematic, including capacitors, inductors, voltage regulators, sensors, etc. Ensure that the components meet the specifications and possess sufficient voltage, current, and temperature characteristics.

- Perform Layout Design: Place the selected components on the circuit board and perform layout design. Consider factors such as electromagnetic compatibility, thermal management, and signal interference. Ensure that the interconnections between components are kept as short as possible, following best layout practices.

- Conduct Routing Design: Based on the layout design, perform routing design for the circuit board. Ensure isolation between signal and power lines, use appropriate trace widths and spacing to avoid interference and signal loss.

- Design Ground Planes: Design appropriate ground planes to ensure a good ground reference plane and minimize ground loop interference.

- Optimize Circuit Board Layout and Routing: Optimize layout and routing based on design rules and guidelines to improve the performance, stability, and reliability of the circuit board.

- Manufacture and Assemble the Circuit Board: Manufacture and assemble the designed circuit board. Choose suitable materials, processes, and manufacturers to ensure quality control and proper assembly techniques.

- Test and Validate: Conduct testing and validation of the manufactured circuit board to ensure it meets the design specifications and functional requirements. Perform functional testing, electrical performance testing, temperature testing, etc., to ensure proper operation and stable performance of the circuit board.

Before designing, it is essential to carefully read the technical specifications of the brushless DC motor and driver and choose suitable electronic components and design solutions based on the requirements. Here are some considerations and possible electronic components you can take into account:

- Motor Driver: You need to select a suitable motor driver circuit to control the brushless DC motor. Common drivers include Electronic Speed Controllers (ESCs) or brushless DC motor controllers. These drivers typically offer current regulation, speed control, and reverse functionality.

- Control Signal Interface: You need to provide an interface on the circuit board for communication with the driver. PWM (Pulse Width Modulation) signals are commonly used to control the motor’s speed and direction. Ensure that the circuit board has sufficient pins and connectors to connect the driver and external control devices such as remote controllers or speed regulators.

- Power Management: Providing proper power management for the brushless DC motor and other circuits is crucial. Consider the power input voltage range, current requirements, and aspects such as overcurrent and overheating protection. Choose appropriate power management circuits and components to ensure the proper operation of the circuit board and motor.

- Signal Isolation and Filtering: To ensure stability and immunity to interference, you may need to consider using signal isolators and filters. Signal isolators can isolate the motor’s noise interference, while filters can remove high-frequency noise on power and signal lines.

- Protection Circuits: To protect the circuit board and motor from potential faults and overloads, you can consider adding protection circuits such as overcurrent protection, overheat protection, and short circuit protection. These protection circuits can enhance the reliability and safety of the circuit board and motor.

- Sensors and Feedback: If you desire advanced functionalities in the ceiling fan, such as temperature monitoring, speed feedback, or position feedback, you can consider adding corresponding sensors and feedback circuits. These circuits can provide more precise control and monitoring capabilities.

By learning the steps of design a circuit board for BLCD ceiling fan and the importance of choosing electronic components, hope our this blog has helped with your work. And also, you can contact us for your project. At SuperPCBA, our key strengths lie in our robust design capabilities, meticulous quality control, and competitive pricing. Our experienced team of engineers possesses in-depth knowledge and expertise in BLDC fan circuit board design, ensuring optimal performance and efficiency. We adhere to stringent quality control measures at every stage of the manufacturing process to guarantee the highest level of product reliability and durability. Now, click the inquiry button and contact with us!