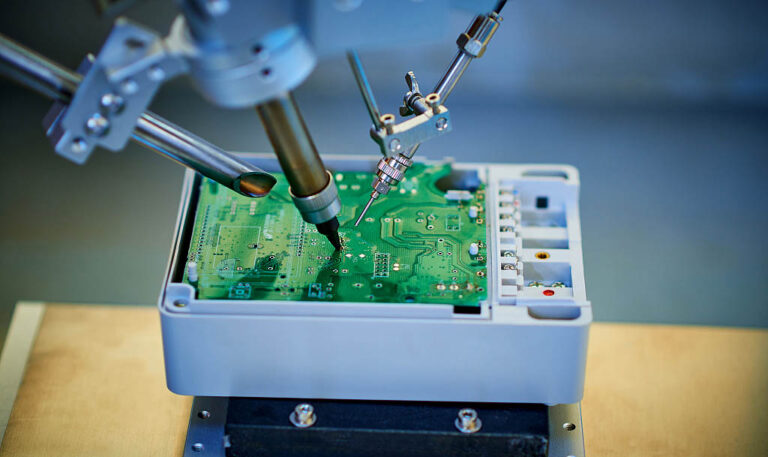

Box build assembly refers to the process of assembling and integrating various components, sub-assemblies, and sometimes printed circuit boards (PCBs) into a final product or system. In the context of PCBs, box build assembly PCB typically refers to the assembly of a PCB into a final enclosure or casing, which may include other components such as wiring, displays, switches, connectors, and power supplies.

In essence, box build assembly PCB involves taking a completed or partially completed PCB and integrating it with other components and subsystems to create a finished product that meets the requirements of the customer. This process can involve a wide range of tasks, including mechanical assembly, wiring and cabling, testing and verification, and final inspection and packaging. Box build assembly PCB is often used in the production of complex electronic systems, such as medical devices, telecommunications equipment, and industrial automation systems.

Here are some potential advantages of box build assembly:

Simplified Supply Chain Management: Box build assembly can simplify the supply chain by consolidating multiple components and subsystems into a single, finished product. This can reduce the number of suppliers and vendors involved in the production process, which can streamline logistics and reduce the risk of supply chain disruptions.

Improved Quality Control: Box build assembly allows for comprehensive testing and verification of the finished product before it is shipped to the customer. This can help ensure that the product meets all quality and performance requirements, which can reduce the risk of field failures and customer complaints.

Faster Time to Market: Box build assembly can help speed up the time to market for new products by reducing the amount of time and effort required to integrate various components and subsystems. This can help companies bring new products to market more quickly, which can be a competitive advantage.

Reduced Labor Costs: Box build assembly can reduce labor costs by consolidating multiple assembly and integration tasks into a single process. This can help reduce the amount of labor required to produce a finished product, which can lower manufacturing costs and improve profitability.

Increased Flexibility: Box build assembly can provide greater flexibility in terms of customization and product configuration. This can allow companies to offer a wider range of product options and variations, which can help meet the needs of a diverse customer base.

Box build assembly is suitable for a wide range of projects that involve the integration of multiple components and subsystems into a final product. Some examples of projects that may benefit from box build assembly include:

Medical Devices: Medical devices often require the integration of complex electronics, sensors, and other components. Box build assembly can help ensure that all components are properly integrated and tested to meet regulatory and safety requirements.

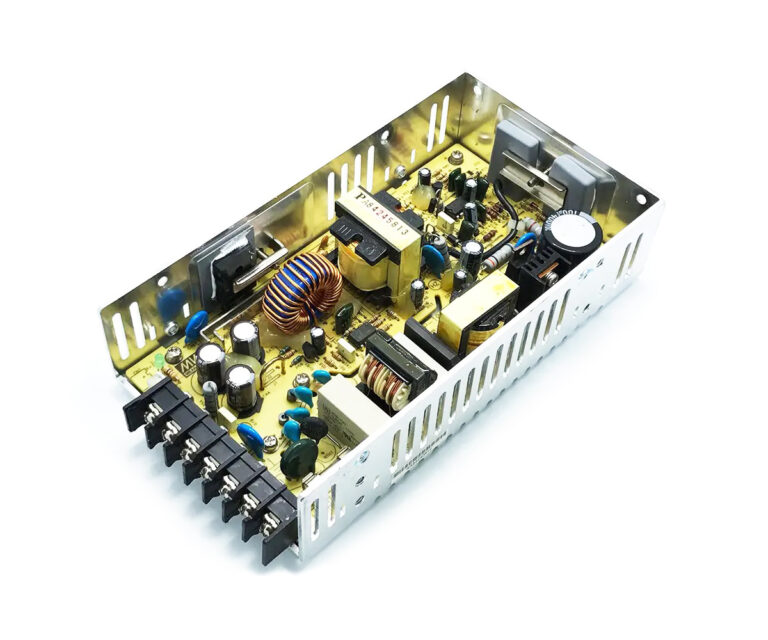

Telecommunications Equipment: Telecommunications equipment often involves the integration of multiple subsystems, including antennas, transceivers, power supplies, and control systems. Box build assembly can help ensure that these subsystems are properly integrated and tested to meet performance and reliability requirements.

Industrial Automation Systems: Industrial automation systems often involve the integration of multiple sensors, actuators, controllers, and other components. Box build assembly can help ensure that these components are properly integrated and tested to meet the needs of the specific application.

Military and Aerospace Systems: Military and aerospace systems often require the integration of complex electronics, sensors, and other components into ruggedized enclosures. Box build assembly can help ensure that these components are properly integrated and tested to meet the demands of harsh environments.

Consumer Electronics: Consumer electronics products often require the integration of multiple components, including displays, speakers, batteries, and control systems. Box build assembly can help ensure that these components are properly integrated and tested to meet the needs of consumers.

Overall, box build assembly can be suitable for any project that requires the integration of multiple components and subsystems into a final product.

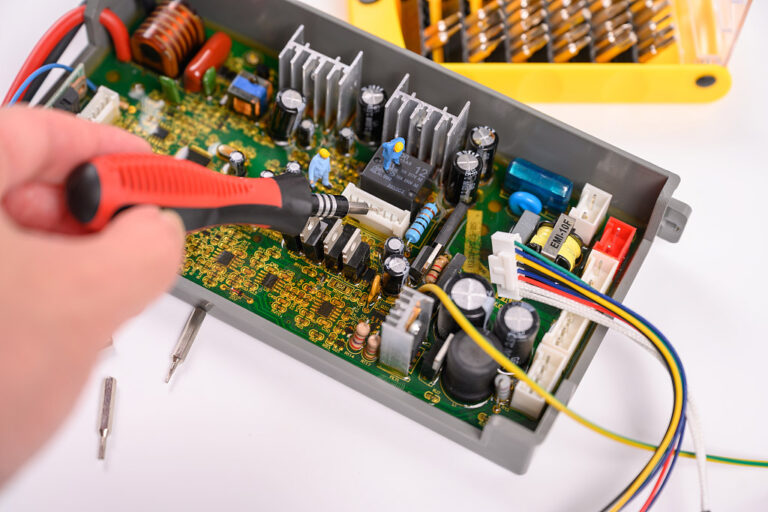

Compared to other types of assembly such as surface mount technology (SMT) assembly or through-hole assembly, box build assembly requires a more comprehensive inspection process due to the complexity and integration of different components.

Some of the differences in inspection between box build assembly and other types of assembly include:

Comprehensive testing: Box build assembly typically involves comprehensive testing of the entire system, including mechanical and electrical testing. This includes functional testing of the software and firmware, as well as verification of the mechanical components.

Integration of subsystems: In box build assembly, subsystems such as power supplies, displays, and sensors are integrated into the final product. This requires additional testing and inspection to ensure that the subsystems are integrated correctly and functioning properly.

Quality control: Box build assembly often involves higher levels of quality control, including incoming inspection of components and sub-assemblies, in-process inspection, and final product inspection. This is due to the higher complexity and importance of the final product.

Documentation: Due to the complexity of box build assembly, there is typically more documentation required to ensure that the assembly process is repeatable and that the final product meets all required specifications.

Overall, the inspection process for box build assembly is more comprehensive and requires more attention to detail compared to other types of assembly due to the complexity and integration of different components.

Get a factory directly price quote with 24 hours.

Pls input your email address correctly!

Make sure your name and email is right.