A 0-ohm resistor may seem like a redundant component at first glance, especially given its name, but it plays an important role in modern circuit design and PCB (Printed Circuit Board) assembly. Often used as a jumper, it facilitates design flexibility, simplifies the manufacturing process, and enhances the overall performance of the circuit. In this article, we will analyze the common applications and practical uses of 0-ohm resistors in various electronic devices.

What is a 0-Ohm Resistor?

A 0-ohm resistor is a special type of resistor that technically has a resistance of nearly 0 ohms. In essence, it behaves like a short circuit or jumper but is integrated into the PCB as a surface-mounted component. Despite being called a “resistor,” its primary purpose is to make connections in the circuit, just like a wire would, but in a more compact and efficient form.

Common Application Scenarios

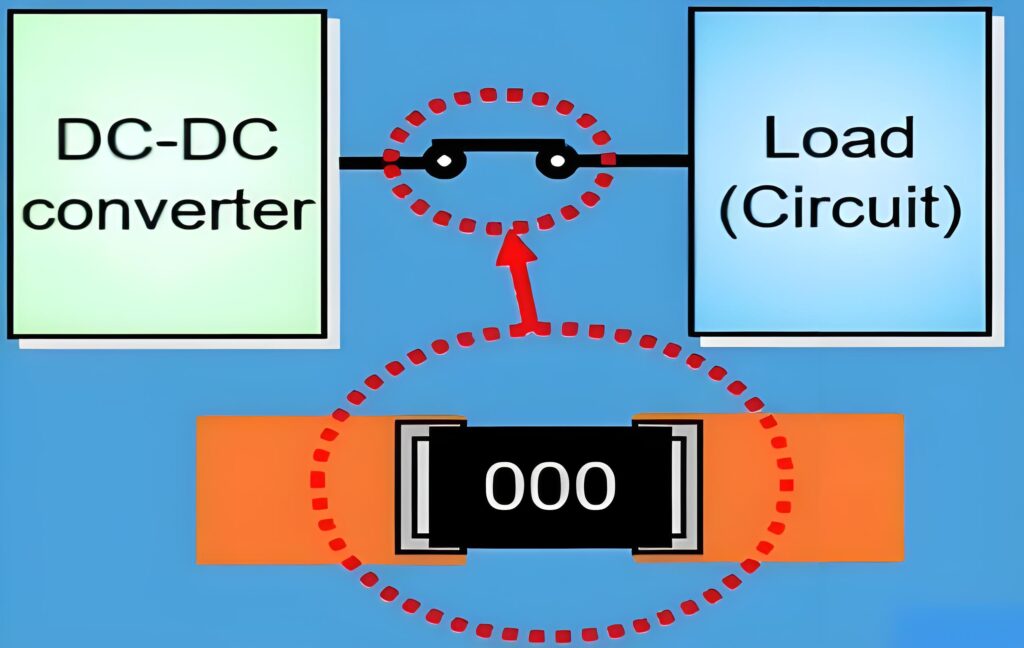

- Jumpers for Circuit Connections: 0-ohm resistors are commonly used as jumpers to create electrical connections between different points on the PCB. They provide a simple and efficient way to complete a circuit without needing to route complex wire traces. This application is particularly useful in multi-layer PCBs or circuits with limited space.

- Design Flexibility: When designing circuits that may undergo future modifications, a 0-ohm resistor can serve as a placeholder. By inserting a 0-ohm resistor, engineers allow for easy redesign and routing of the circuit without needing to alter the entire PCB. This is particularly useful in prototyping and iterative design processes where changes might occur after initial assembly.

- Testing and Prototyping: 0-ohm resistors are often used during the testing and prototyping stages. They provide a convenient way to bridge connections temporarily or to test specific parts of a circuit. If necessary, they can later be replaced with other components based on the test results or requirements.

- Manufacturing and Cost Efficiency: In high-volume PCB manufacturing, the use of 0-ohm resistors helps reduce assembly complexity. Rather than using dedicated jumper wires or manual interventions to make connections, 0-ohm resistors are placed on the PCB using the same automated processes as other resistors, improving efficiency and reducing costs.

- Soldering and Rework: 0-ohm resistors can also be used in situations where rework may be required. During the manufacturing process, if there is a need to adjust the routing or component placements, the 0-ohm resistors can be easily removed or replaced with other components without significant changes to the board layout.

- Electrical and Mechanical Considerations: When routing electrical signals on a PCB, the 0-ohm resistor provides the necessary connection with minimal electrical impedance. It is especially useful for reducing the complexity of signal paths, ensuring a clean signal transmission, and maintaining circuit integrity. Additionally, the 0-ohm resistor helps maintain the mechanical integrity of the PCB by ensuring the correct spacing of components in tight layouts.

Practical Uses of 0-Ohm Resistors

- Reducing PCB Footprint: In compact circuit designs, where space is limited, 0-ohm resistors are used as a space-saving alternative to traditional jumpers. Their small size ensures that they do not take up valuable board real estate, making them ideal for high-density, miniaturized devices.

- Easy Customization: Since 0-ohm resistors can be easily removed or replaced, they are used in designs where future modifications are likely. This is particularly useful in modular circuit designs or products that require customizable options.

- Product Variants and Customization: In some products, different configurations may be needed for different models. By placing 0-ohm resistors in certain locations, manufacturers can create customized versions of the same product with minimal changes to the PCB layout. This reduces the time and cost associated with redesigning the entire board.

- Simplifying Assembly and Repair: Since 0-ohm resistors are compatible with automated assembly processes, they help streamline the manufacturing and repair workflows. They are particularly helpful in reducing manual labor and minimizing assembly errors, especially in high-volume production runs.

Benefits of 0-Ohm Resistors

- Cost-Effectiveness: 0-ohm resistors are inexpensive components, making them a cost-effective solution for routing signals or making circuit connections. Their low cost, along with their ability to replace complex wire jumpers, makes them an attractive option for many applications.

- Minimizing Complexity: In circuit design, 0-ohm resistors reduce the need for complex jumper wires or manual routing. This simplifies the overall design, making it easier to assemble and troubleshoot the PCB.

- Enhanced Circuit Design: 0-ohm resistors provide flexibility in circuit design by allowing the designer to modify routing or make temporary connections. This flexibility allows for more efficient and effective circuit optimization.

Conclusion

Despite their simple appearance, 0-ohm resistors play a critical role in modern PCB design and assembly. They provide essential benefits such as space savings, cost reduction, design flexibility, and ease of assembly and repair. Whether for temporary circuit connections, testing, or manufacturing efficiency, 0-ohm resistors have become an indispensable component in the electronics industry.

By understanding the applications and advantages of 0-ohm resistors, engineers and designers can utilize them to streamline their circuit designs, optimize production processes, and improve overall product performance.