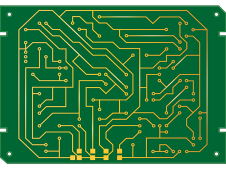

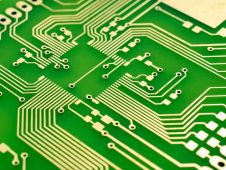

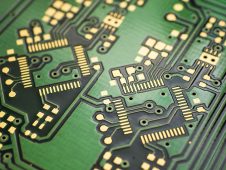

A circuit board, also known as a printed circuit board (PCB), is a board made of insulating material, usually fiberglass or plastic, with conductive pathways etched onto its surface. These pathways, known as traces, connect electronic components such as resistors, capacitors, and integrated circuits, which form an electronic circuit. Circuit boards are used to support and connect electronic components to form various electronic devices.

The development history of PCB boards dates back to the early 1900s when the first circuit boards were developed. These early circuit boards were made using a technique called wire wrapping, in which wires were manually wrapped around posts to connect electronic components.

In the 1920s, printed circuit boards (PCBs) were developed using a photographic process. However, this process was limited to single-sided boards with no plated through-holes.

In the 1950s, the use of PCBs became more widespread due to advances in technology, including the development of multi-layer boards with plated through-holes. This allowed for more complex electronic devices to be developed.

Since then, the development of PCBs has continued, with improvements in materials, processes, and technologies. Today, PCBs are essential components in the electronics industry, used in a wide range of devices, from simple household appliances to complex medical equipment and spacecraft.

There are several types of PCB boards, including:

Single-sided PCBs – These boards have components and traces on only one side, making them simpler and less expensive to manufacture.

Double-sided PCBs – These boards have components and traces on both sides, allowing for more complex circuits to be designed.

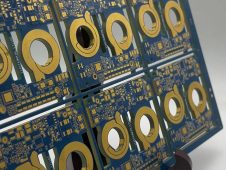

Multi-layer PCBs – These boards consist of multiple layers of insulating material and conductive pathways, allowing for even more complex circuits to be created. Multi-layer PCBs are commonly used in high-end electronics, such as computers and smartphones.

Rigid PCBs – These boards are made of rigid materials such as fiberglass, and are commonly used in electronic devices that require stability and durability.

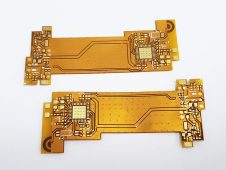

Flexible PCBs – These boards are made of flexible materials, such as plastic or polyimide, and can be bent or folded to fit into tight spaces. They are commonly used in wearable electronics, medical devices, and automotive applications.

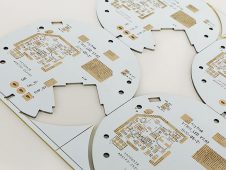

High-frequency PCBs – These boards are designed to work at high frequencies, and are commonly used in radio and telecommunications equipment.

HDI (High-Density Interconnect) PCBs – These boards have a higher density of components and interconnections, allowing for smaller and more complex devices to be manufactured. They are commonly used in smartphones, tablets, and other portable electronics.

Metal core PCBs – These boards have a metal core, typically made of aluminum, that provides better heat dissipation than standard PCBs. They are commonly used in high-power LED lighting and automotive applications.

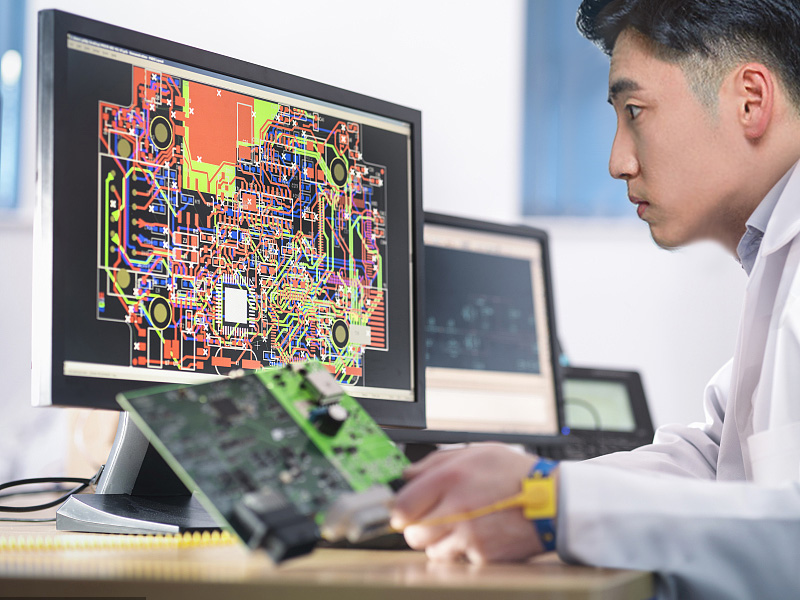

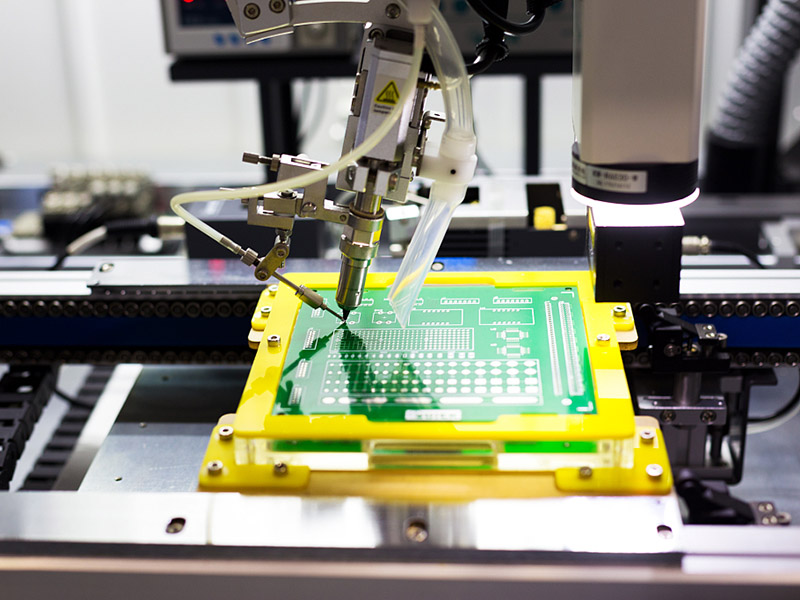

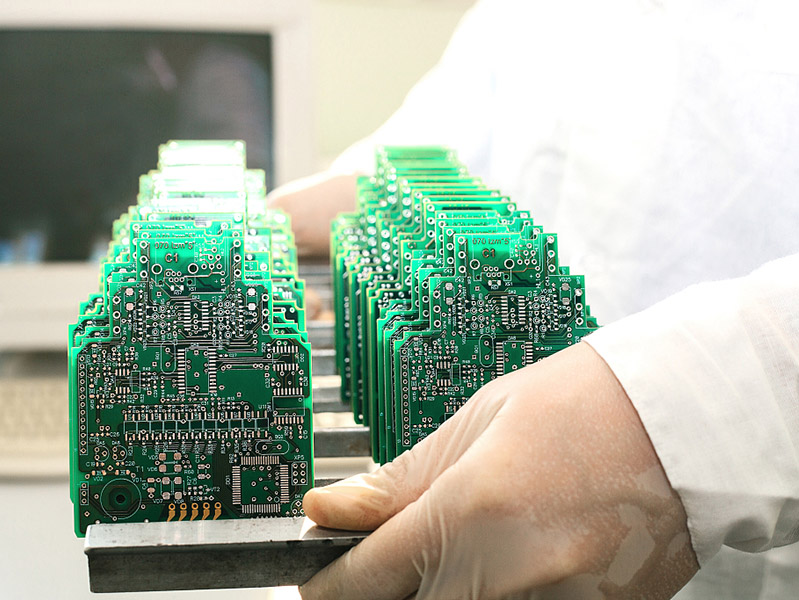

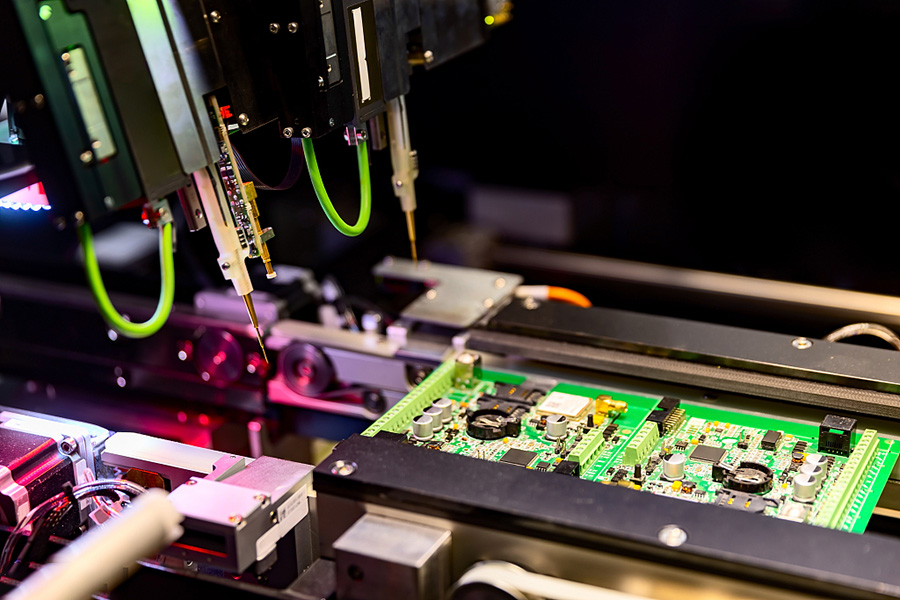

The manufacturing of printed circuit boards (PCBs) is an intricate and sophisticated process that demands a high level of complexity. It requires the factory to have a wealth of production experience and a well-established quality assurance system to ensure the final product meets the required standards of quality and reliability.

The production process of PCB boards generally involves the following 24 steps:

PCB boards are used in a wide range of electronic devices, including:

Computers – Circuit boards are used in computer motherboards, graphics cards, and memory modules.

Smartphones and tablets – Circuit boards are used in smartphones and tablets to power the device and provide connectivity.

Televisions and home entertainment systems – Circuit boards are used in televisions and home entertainment systems to control the functions of the device.

Medical equipment – Circuit boards are used in a variety of medical equipment, such as MRI machines, CT scanners, and blood glucose monitors.

Automotive systems – Circuit boards are used in a range of automotive systems, including engine management systems, airbag control units, and entertainment systems.

Aerospace and defense – Circuit boards are used in satellites, aircraft control systems, and military equipment.

Industrial automation – Circuit boards are used in industrial control systems, such as programmable logic controllers (PLCs), to control machinery and processes.

Consumer electronics – Circuit boards are used in a variety of consumer electronics, such as cameras, game consoles, and smart home devices.

Overall, PCB boards are of significant importance in modern society, and their impact can be seen in various aspects of our lives.

In summary, the significance of circuit boards in modern society cannot be overstated. They have enabled the development of modern electronics, increased efficiency and productivity, facilitated medical advancements, improved communication and connectivity, and boosted the economy.

Get a factory directly price quote with 24 hours.

Pls input your email address correctly!

Make sure your name and email is right.