1. Introduction: The First Line of Defense for High-Quality PCBs

In today’s electronic products, printed circuit boards (PCBs) are not just the foundation of circuit connectivity—they’re the backbone of system reliability. Whether it’s a smartwatch, automotive electronics, or an industrial controller, the quality of the PCB directly affects the stability of the final product. A tiny short or open circuit could lead to malfunction, or worse, complete failure.

Among the various steps in PCB manufacturing, electrical testing is the final and critical checkpoint. It helps uncover hidden issues and ensures that only defect-free boards are delivered. One of the most effective testing methods is the Flying Probe Test (FPT), known for its flexibility, speed, and precision—making it essential for small-batch, high-mix, and high-precision PCB production.

In this article, we’ll walk you through how flying probe testing works, why it matters, and how our factory leverages this technology to uphold the highest quality standards.

2. What is Flying Probe Testing?

Flying Probe Testing (FPT) is a method of verifying electrical connectivity using high-speed, computer-controlled probes—without the need for custom test fixtures. It’s widely used to detect open circuits, shorts, and incorrect connections on a PCB and is a vital tool in modern electronics manufacturing.

2.1 How It Works

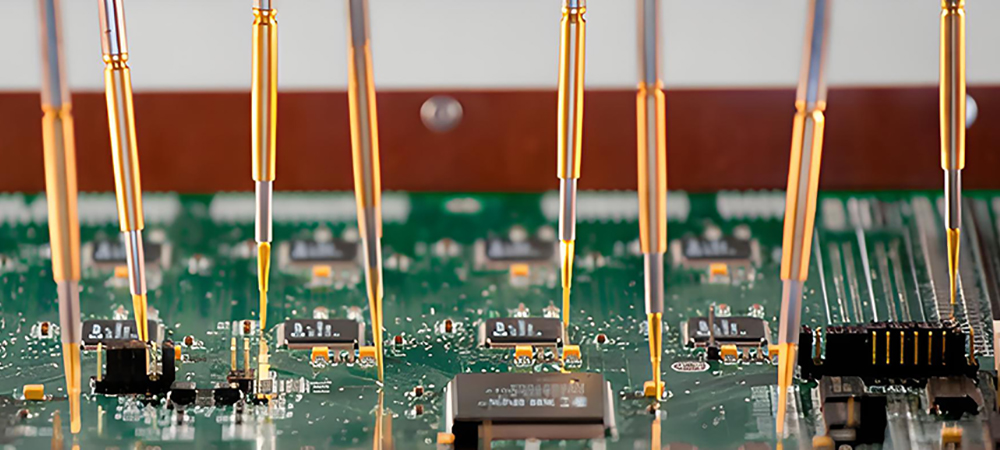

FPT machines are equipped with multiple probes (usually between 2 to 8) that move rapidly and precisely across the board. Under software control, these probes make contact with pads or test points on the PCB one by one.

When two probes land on designated test points, a small current is applied, and the system measures resistance or voltage changes to determine whether the circuit is intact or faulty. Since no fixed test fixture is required, the test programs can be generated quickly from design data, making FPT ideal for prototypes, small batches, and boards with complex layouts.

2.2 Key Differences from Traditional Fixture Testing

Fixture-based (bed-of-nails) testing is fast and cost-effective for mass production but requires a dedicated fixture for each board design. These fixtures are expensive and time-consuming to build.

Flying probe testing offers significant advantages:

- No fixture needed—lower cost and faster setup

- Supports any board shape or trace layout

- Ideal for rapid prototyping, design verification, and complex boards

- Capable of testing fine-pitch and high-density layouts

2.3 Common Applications

Flying probe testing is widely used in:

- PCB prototyping and small-volume production

- Rapid NPI (New Product Introduction) validation

- High-mix, low-volume manufacturing

- Quality checks on multilayer, high-precision, and high-density PCBs

- Failure analysis and repair of defective boards

3. Why Flying Probe Testing Matters

As electronics continue to shrink and increase in complexity, traditional fixture testing struggles to keep up. FPT has become the preferred solution for many manufacturers due to its precision, flexibility, and fast response.

Here are some of its major advantages:

3.1 No Fixtures, Lower Costs, Faster Turnaround

One of FPT’s biggest benefits is the elimination of test fixture development. This not only cuts costs but also significantly shortens the lead time—especially valuable during early-stage design, prototyping, or pilot runs.

3.2 Tailored for High-Mix, Low-Volume Production

In environments where many different boards are produced in small quantities, fixture testing is impractical. FPT allows fast switching between test programs with no hardware changes—ideal for modern, flexible manufacturing lines.

3.3 High Precision for High-Density Designs

Modern flying probe testers use high-resolution cameras and ultra-precise motion systems to achieve micron-level accuracy. This allows them to handle tight pitch designs (as fine as 50μm), such as BGA, HDI, or multilayer boards, with confidence.

3.4 Electrical Characterization and Full Traceability

Beyond simple continuity tests, FPT systems can measure resistance, capacitance, and diode voltage drops to detect subtle electrical issues. All test data is stored and traceable—supporting robust quality control and failure analysis.

3.5 Automation Minimizes Human Error

Many FPT machines now feature auto-alignment, auto height calibration, and even automatic board loading—boosting efficiency while reducing operator errors and ensuring consistent quality.

4. Our Flying Probe Testing Capabilities

As a PCB manufacturer focused on both quality and efficiency, we understand the vital role of electrical testing in delivering reliable products. To meet our customers’ demands for high performance and fast delivery, we’ve invested in advanced flying probe systems that cover a wide range of board types.

4.1 Advanced Equipment for a Variety of Boards

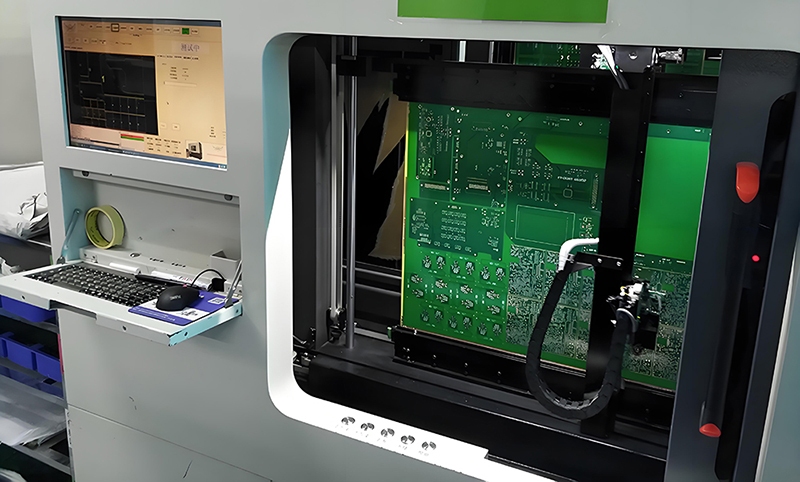

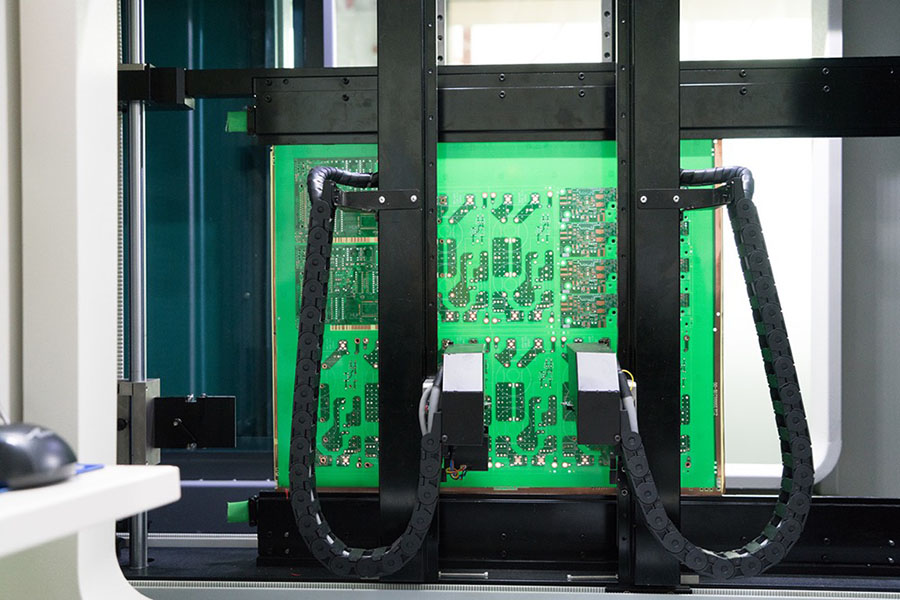

Our FPT lineup includes state-of-the-art testers. These machines support multi-probe parallel testing and are compatible with single and double-sided boards, multilayer designs, and HDI boards—serving both prototypes and small production runs.

4.2 High Precision for Complex Designs

Our systems offer Xμm positioning accuracy and can test minimum pad spacing down to Yμm. This allows us to reliably test even the most demanding high-density layouts with minimal false calls or missed defects.

4.3 Streamlined Testing Process for Efficiency

We’ve standardized our FPT workflow:

- CAM file import → Automatic test program generation → Auto alignment → Electrical testing → Result analysis

- Automated reports are generated for every job

- Seamless integration with AOI and functional test stages for comprehensive quality assurance

4.4 Rapid Turnaround for Prototypes

We offer a fast-track testing service for urgent orders, including 24-hour prototype testing support—helping customers accelerate their product development cycles.

5. Real-World Applications of Flying Probe Testing

Flying probe testing isn’t just a process—it’s a key tool for ensuring product quality and supporting customer success. Here are two examples of how we’ve used FPT to create real value:

Case 1: Detecting Hidden Design Flaws

A client in the smart security sector was prototyping a new control board with complex multilayer routing and BGA components. During FPT, we found an intermittent short between two critical points—something invisible to both the naked eye and AOI inspection.

Our engineers collaborated with the client’s team, analyzing the issue and identifying improper internal layer spacing due to stack-up design. They revised the layout before mass production, avoiding costly field failures and cutting weeks off the development timeline.

Case 2: Seamless Testing for Small-Batch Orders

Another client in industrial control places frequent small-volume orders for various models—each requiring high test accuracy and tight delivery schedules. Our FPT system’s fast-switching capability enabled us to test multiple product types daily with zero downtime.

The client remarked, “Your testing flexibility and responsiveness make you our most reliable partner for pilot production.”

6. Why Customers Choose Us

In PCB manufacturing, success isn’t just about having the right equipment—it’s about attention to detail, commitment to quality, and a strong sense of responsibility.

Here’s why more and more customers partner with us:

6.1 Quality-First Mindset

Every PCB that leaves our facility is treated like a mission-critical part. Flying probe testing is just one layer of our quality control, working alongside AOI, functional testing, and visual inspections to create multiple lines of defense.

6.2 Agile and Responsive

Need to revise your design last minute? Launch a prototype urgently? We can adapt FPT programs overnight and put in the extra hours to meet your deadlines. In today’s fast-paced development cycles, time is everything.

6.3 Engineering Support from Start to Finish

Our engineers collaborate closely with customers, offering support from Gerber review to test point optimization. We’re not just testing boards—we’re solving problems together.

6.4 Trusted by Long-Term Partners

Many customers who try us once become repeat clients—and even refer us to their peers. That trust is the result of consistent delivery, solid communication, and a commitment to excellence.

7. Conclusion: Quality Backed by Testing, Trust Built on Expertise

Flying probe testing isn’t just about checking for shorts or opens—it reflects our promise to deliver reliable PCBs. In a world where speed and reliability define success, we use cutting-edge tools, standardized processes, and a professional mindset to ensure every board is built to perform.

If you’re looking for a PCB partner with strong testing capabilities, fast turnaround, and engineering collaboration, we’d love to work with you. Whether it’s a prototype or a production run, we’re here to support you with precision and care.

📧 Reach out to us at: sales@superpcba.com

Let’s build better electronics—together.