In modern electronic devices, control boards serve as the core components that enable complex functionalities, and relays are indispensable elements on these boards. Relays function not just as switching components, but also as key factors in ensuring the stable operation of devices. From the perspective of a control board assembly engineer, this article delves into the fundamental principles of relays, their selection criteria, installation layout, and the processes of testing and maintenance. The goal is to provide a comprehensive understanding of how relays are applied in control boards. Today, we will explore the principles, types, and roles of relays in control board design and manufacturing.

1. Basic Principles and Types of Relays

Working Principle: A relay is an electronic component that uses electromagnetic principles to control circuit switches. Its core components include a coil, armature, spring, and a set of contacts. When current passes through the relay’s coil, it generates a magnetic field that attracts the armature. The movement of the armature opens or closes the contacts, thereby controlling the circuit’s on-off state. When the coil current stops, the magnetic field disappears, and the spring returns the armature to its original position, restoring the contacts to their initial state. This simple yet reliable electromagnetic mechanism makes relays essential components in automation control.

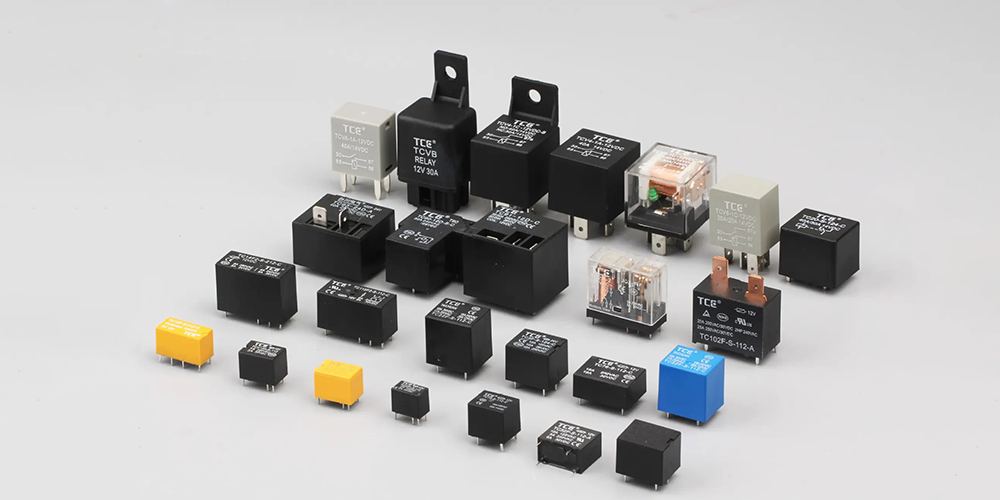

Main Types:

- Electromagnetic Relay (EMR):

- Features: Uses an electromagnetic coil to drive the contacts to switch. It is simple in structure and low in cost.

- Applications: Widely used in low-frequency, low-power circuit control, such as household appliances, automotive electronics, and industrial automation.

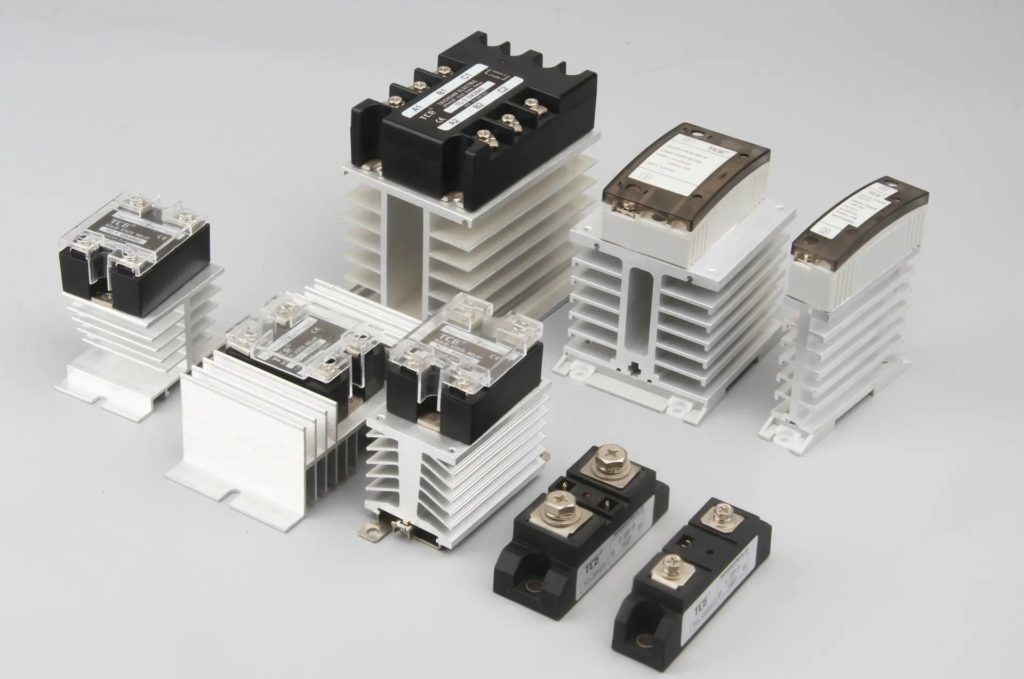

- Solid-State Relay (SSR):

- Features: No mechanical moving parts; circuit switching is achieved through semiconductor devices, offering advantages like high speed, long life, and noiseless operation.

- Applications: Suitable for high-frequency, high-current scenarios, such as industrial automation, heating equipment, and lighting control.

- Reed Relay:

- Features: Uses reed contacts enclosed in a glass tube that open and close under a magnetic field. It is small in size and has a fast response.

- Applications: Ideal for applications requiring fast response and small space, such as communication equipment, sensor interfaces, and security devices.

- Thermal Relay:

- Features: Based on the thermal expansion properties of bimetallic strips, it controls circuit on-off through temperature changes, primarily used for overload protection.

- Applications: Commonly used in devices requiring overload protection, such as motors and heaters.

Each type of relay has its unique advantages and suitable applications. Engineers should choose the appropriate type of relay based on specific application requirements to ensure system stability and efficiency.

2. Applications of Relays in Control Boards

Specific Application Examples:

- Switching Circuits:

- Application: Relays are commonly used as circuit switches on control boards to isolate the main circuit from the control circuit. By using a low-power signal to control a high-power circuit, safe and efficient switching operations are achieved. For example, in smart home control boards, relays can control the on-off states of lighting, electric windows, and other devices.

- Circuit Isolation:

- Application: Relays provide circuit isolation, protecting low-voltage control circuits from the effects of high voltage or high current. In industrial control boards, relays can isolate control signals from load signals, ensuring the stable operation of the system.

- Load Control:

- Application: Relays can directly control various loads, such as motors, electric heaters, and lamps. In the control board of an electric bed, relays can control the motor’s direction and speed to achieve the lifting function of the bed.

Selection Criteria:

- Voltage and Current:

- Considerations: When selecting a relay, it is necessary to ensure that its rated voltage and current meet the actual application requirements. The specifications of voltage and current directly affect the reliability and safety of the relay.

- Example: In a home appliance control board, if the load being controlled is a 220V appliance, a relay with a rated voltage of at least 250V should be selected to provide sufficient safety margin.

- Switching Speed:

- Considerations: The switching speed of a relay (i.e., the opening and closing time of the contacts) is critical for certain applications, especially in control systems that require fast response.

- Example: In the control board of an automated production line, the relay’s switching speed determines the system’s responsiveness, impacting overall production efficiency.

- Size:

- Considerations: The space on a control board is limited, and the size of the relay must fit the PCB layout. Smaller relays can save space, but their electrical performance must be balanced.

- Example: In compact devices, such as the control board of a portable medical device, selecting small-sized relays helps achieve a more compact design.

- Lifespan:

- Considerations: The mechanical and electrical lifespan of a relay determines its reliability in long-term operation. Mechanical lifespan refers to the number of contact openings and closings, while electrical lifespan refers to the number of openings and closings under the rated load.

- Example: In industrial control boards, where relays need to operate frequently, high-lifespan relays can reduce maintenance costs and extend the system’s continuous operating time.

Selecting the right relay is a critical step in control board design. Engineers must consider these factors comprehensively to ensure the system’s efficiency, stability, and safety.

Conclusion

In summary, relays play a crucial role in control board design and manufacturing. From selection to installation, to testing and maintenance, every step affects the performance and reliability of the control board. As technology advances, relays continue to evolve, offering more intelligent and efficient solutions. For control board engineers, mastering the techniques of relay application and staying abreast of the latest trends not only helps improve product quality but also extends the lifespan of devices, providing customers with superior solutions.