With the continuous development of electronic technology, the application scope of PCBs is becoming increasingly extensive, making them integral components in various electronic devices and playing critical roles in various applications. Among these, FR4 PCBs and Aluminum PCBs are two common types of PCBs with distinct advantages and applications, capable of meeting the design and manufacturing requirements of many electronic products. Let’s delve into these two most common types of PCB substrates to understand why they are widely used and what sets them apart, thereby aiding in the selection of suitable PCB substrates for our projects.

Reasons for the Wide Use of FR4 and Aluminum-Based PCBs

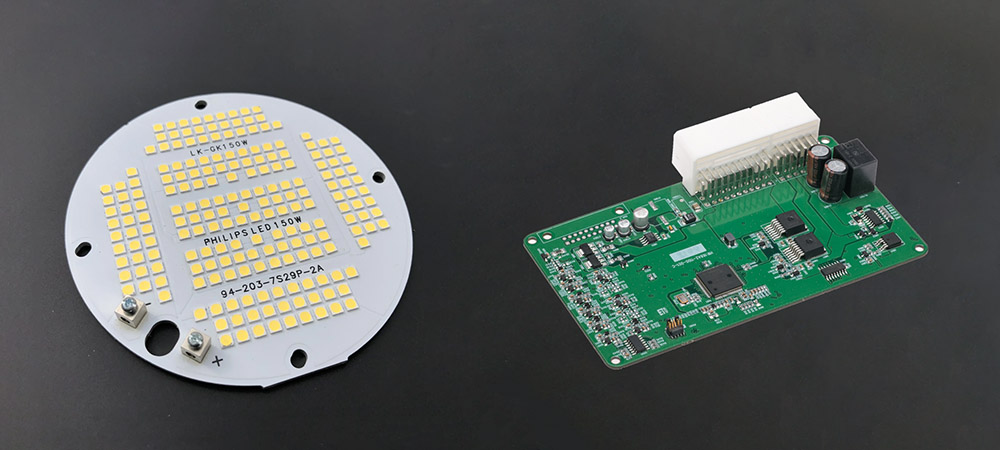

FR4 and aluminum-based boards (Metal Core PCB, or MCPCB) are the most commonly used circuit board substrates due to their respective characteristics, which allow them to meet the design and manufacturing requirements of many electronic products.

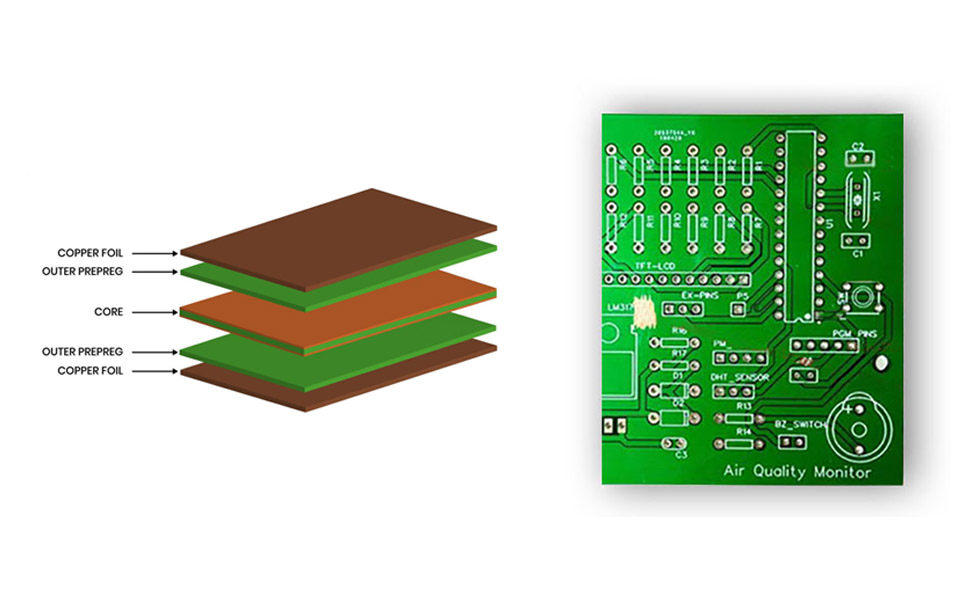

FR4 Boards (Glass Fiber Reinforced Epoxy Resin PCB):

- Wide Applicability: FR4 boards have good mechanical strength and insulation performance, suitable for the manufacture of most general electronic devices, such as computers, communication equipment, and consumer electronics.

- Good Processing Performance: FR4 boards are easy to process and manufacture, with relatively low costs and mature processing technology, capable of meeting various complex design requirements.

- Reliability and Stability: FR4 boards exhibit stable electrical characteristics and mechanical performance under common working conditions.

- Electrical Performance: FR4 boards have moderate dielectric constant and dielectric loss factor, suitable for most low-frequency and medium-frequency applications.

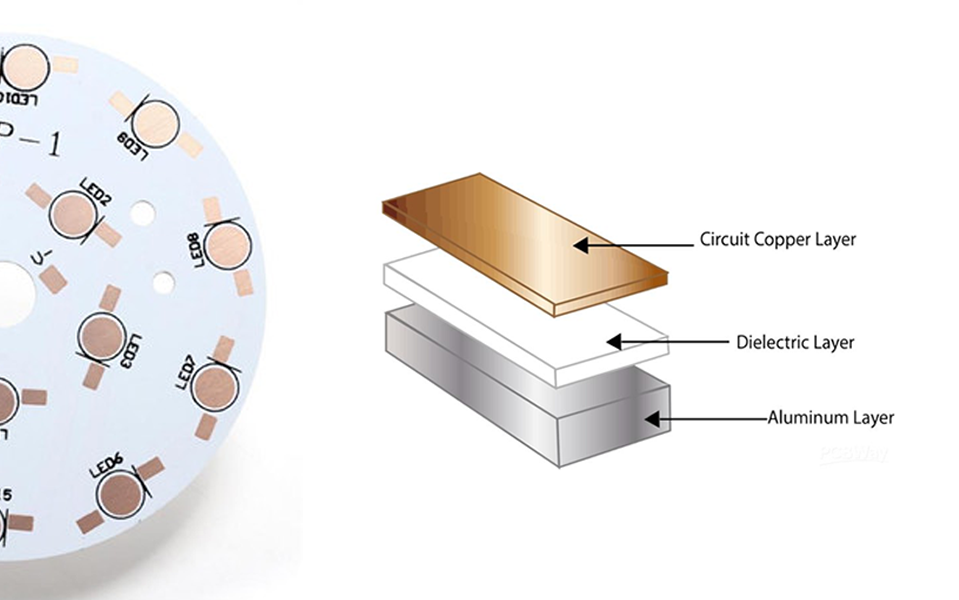

Aluminum-Based Boards (Metal Core PCB, MCPCB):

- Excellent Heat Dissipation: Aluminum-based boards have excellent thermal conductivity, effectively transferring heat from electronic components to the external environment, suitable for electronic devices requiring high power and heat, such as LED luminaires and power modules.

- Matching Thermal Expansion Coefficient: The thermal expansion coefficient of aluminum-based boards matches well with many electronic components (such as LED chips), reducing stress and damage caused by temperature changes.

- Lightweight Design: Aluminum-based boards are relatively lightweight, beneficial for product design and manufacturing, especially in applications that demand light weight and high heat dissipation requirements.

- High-Temperature Resistance: Aluminum-based boards exhibit high temperature resistance, suitable for electronic devices operating in high-temperature environments.

In summary, FR4 boards and aluminum-based boards (MCPCB) possess unique advantages and applicability, enabling them to meet the design and manufacturing requirements of different electronic products, hence widely used in the electronics manufacturing industry. Choosing the appropriate circuit board substrate requires comprehensive consideration of specific application requirements, performance needs, and cost considerations. Let’s further analyze the differences between these two substrate types to assist in making appropriate choices when needed.

Differences Between FR4 PCB and Aluminum PCB

Aluminum-based circuit boards (Aluminum PCB) and FR4 circuit boards (FR4 PCB) exhibit significant differences in multiple aspects, detailed below with supporting data:

Thermal Conductivity:

- Aluminum-based PCBs have far superior thermal conductivity compared to FR4 PCBs. The thermal conductivity of aluminum ranges from 200-250 W/m·K, whereas FR4 typically ranges between 0.25-0.35 W/m·K. This means that aluminum-based PCBs can more effectively transfer and dissipate heat, suitable for applications with high power density and elevated temperatures.

- FR4, composed mainly of glass fiber-reinforced epoxy resin, exhibits poorer thermal conductivity and is generally unsuitable for applications requiring efficient heat dissipation.

Coefficient of Thermal Expansion:

- FR4 PCBs experience significant differences in coefficient of thermal expansion along the board thickness direction: copper has a coefficient of thermal expansion of 17×10^-6 cm/cm℃, while FR4 boards exhibit 110×10^-6 cm/cm℃, resulting in potential discrepancies in substrate material expansion, leading to fractures in copper traces and plated-through holes, thereby affecting product reliability.

- The coefficient of thermal expansion for aluminum substrates is 50×10^-6 cm/cm℃, smaller than that of typical FR4 boards and closer to that of copper foil, contributing to enhanced quality and reliability of printed circuit boards.

Mechanical Strength:

- Due to the characteristics of the metal substrate, aluminum-based PCBs possess higher mechanical strength and rigidity, capable of supporting more electronic components and weight.

- FR4 PCBs exhibit good mechanical strength and rigidity, suitable for supporting and securing most electronic products.

Thickness:

- Aluminum-based PCBs are typically thinner, with a standard thickness of 1.0mm or less, suitable for applications with limited space.

- FR4 PCBs offer a broader thickness range and can be single-layer, double-layer, or multi-layered, catering to different circuit design complexities and functional requirements.

Number of Layers:

- Aluminum-based PCBs typically have fewer layers, commonly single or double-layered.

- FR4 PCBs can be single-layer, double-layer, or multi-layered, accommodating varying circuit design complexities and functional requirements.

Applications:

- Aluminum-based PCBs are primarily used in applications requiring high thermal management, such as LED lighting, automotive electronics, power modules, etc.

- FR4 PCBs are suitable for general electronic circuit applications, including household appliances, communication devices, computers, etc., encompassing scenarios with lower thermal management requirements.

Manufacturing Cost:

- The manufacturing cost of aluminum-based PCBs is usually higher, primarily due to material costs and manufacturing process complexities.

- FR4 PCBs have relatively lower manufacturing costs, attributed to inexpensive materials and relatively simpler manufacturing processes.

In conclusion, with specific data support and comparative analysis, we can gain a clearer understanding of the differences between aluminum-based PCBs and FR4 PCBs in terms of thermal conductivity, mechanical strength, thickness and number of layers, applications, and manufacturing costs. If different thicknesses of PCBs are required, FR4 PCBs are the optimal choice. However, for PCBs with excellent electromagnetic shielding and heat dissipation capabilities, aluminum-based PCBs should be chosen.

Conclusion

In summary, there are significant differences between aluminum-based PCBs and FR4 PCBs in terms of materials, thermal conductivity, coefficient of thermal expansion, lamination, mechanical strength and rigidity, thickness, and applications. Choosing the appropriate PCB type for specific applications is crucial because it directly impacts the performance and stability of electronic devices. Aluminum-based PCBs are suitable for applications requiring high thermal conductivity and electrical conductivity, while FR4 PCBs are suitable for common electronic circuits. Understanding these differences can help engineers and designers make informed choices to meet the needs of their projects.

With over a decade of experience in PCB production, SuperPCBA has partnered with clients worldwide to manufacture high-quality products, establishing a strong presence in the market. We welcome both new and existing customers to inquire about quotations and samples. Feel free to contact us anytime at sales@superpcba.com if you have any inquiries.