If you are involved in the control board industry, you must be very familiar with communication protocols. With the development of technology and the continuous upgrading of control boards, communication protocols related to control boards are also constantly evolving, playing a crucial role in the development of control boards. Communication protocols ensure the interconnection and interoperability of various devices, enabling the fulfillment of more complex functional requirements in technological advancements. Today, let me, as an engineer at SuperPCBA, share insights into communication protocols related to control boards.

What is a Communication Protocol?

A communication protocol is a set of rules and agreements used in communication systems to define the format, encoding, transmission rate, error detection, correction, and other rules for data transmission, enabling the sending and receiving parties to interpret and process data correctly. Communication protocols define data formats, communication rates, error detection and correction, protocol rules, control signals, and other elements. Adhering to communication protocols in product design ensures that communication parties can exchange data and communicate correctly and reliably.

Why Control Boards Need Communication Protocols

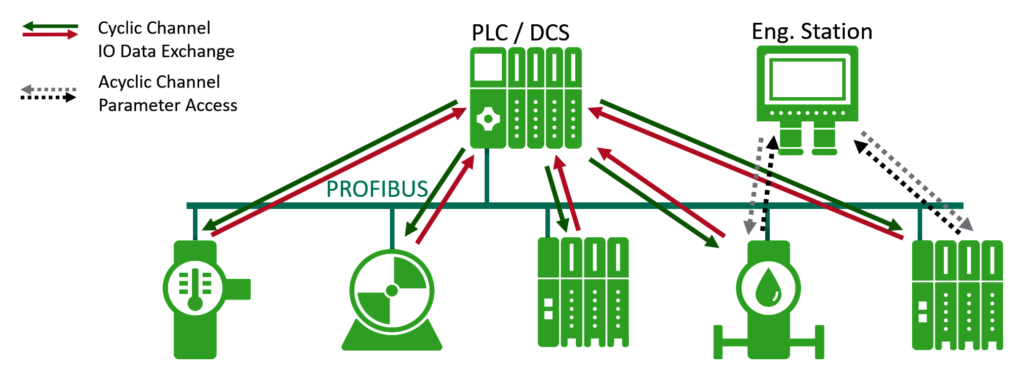

With the development of technologies such as the Internet of Things and smart devices, various new communication protocols continue to emerge, such as wireless communication protocols like Bluetooth, Wi-Fi, Zigbee, as well as industrial control communication protocols like CAN and Modbus. These communication protocols play crucial roles in different fields and various application scenarios.

In the development process of control boards, communication protocols play a vital role:

Interconnection of Devices: Control boards often need to exchange data and communicate with other devices. Communication protocols enable different devices to connect and exchange data with each other, facilitating interconnection between devices.

Data Transmission: Control boards need to transmit data with external devices or networks. Communication protocols specify the format and communication methods for data transmission, ensuring accurate and efficient data transmission.

System Integration: Communication protocols help integrate different systems, enabling control boards to work collaboratively with other systems to achieve more complex functionalities.

Remote Monitoring and Control: Some communication protocols also support remote monitoring and control functions, allowing users to monitor and control the working status of control boards remotely via networks or wireless signals.

In summary, communication protocols play a crucial role in the development of control boards, facilitating the interconnection between control boards and other devices, enabling more complex functionalities, and broader applications.

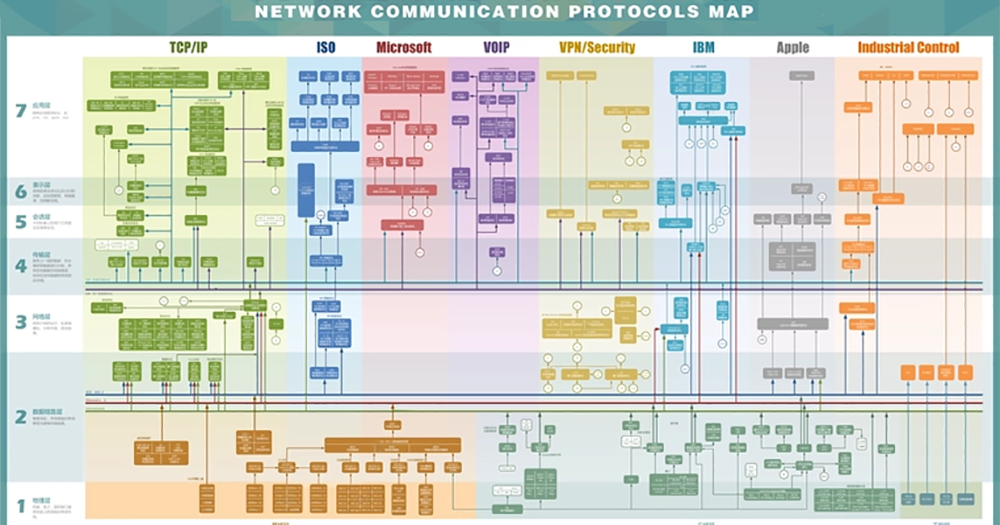

Common Communication Protocols for Control Boards

There are various communication protocols for control boards, and choosing the appropriate one depends on factors such as application scenarios, hardware platforms, and communication requirements. Here are some common communication protocols for control boards:

UART (Universal Asynchronous Receiver-Transmitter): UART is a serial communication protocol used for data transmission between devices. It is a simple, bidirectional, point-to-point communication protocol commonly used to connect microcontrollers, sensors, and peripheral devices.

SPI (Serial Peripheral Interface): SPI is a synchronous serial communication protocol used for high-speed data transmission between devices. It typically consists of one master device and multiple slave devices, supporting full-duplex communication and high-speed transmission. SPI is commonly used to connect memory, sensors, displays, and other peripheral devices.

I2C (Inter-Integrated Circuit): I2C is a serial communication protocol used for data transmission between devices. It supports multi-master, multi-slave communication and uses a two-wire interface (serial data line SDA and serial clock line SCL). I2C is commonly used to connect various integrated circuits, sensors, and memory devices.

CAN (Controller Area Network): CAN is a serial communication protocol used for data transmission in automotive, industrial control, and other fields. It features high reliability, interference resistance, and real-time capabilities and is commonly used to connect onboard electronic devices and industrial control equipment.

Ethernet: Ethernet is a local area network communication protocol based on the TCP/IP protocol suite used for data transmission between devices. It supports high-speed data transmission and remote communication and is commonly used to connect computers, network devices, and IoT devices.

USB (Universal Serial Bus): USB is a universal serial bus interface standard used for data transmission and communication between computers and external devices. It features convenient plug-and-play, high-speed transmission, and power supply capabilities and is commonly used to connect external storage devices, printers, cameras, and other devices.

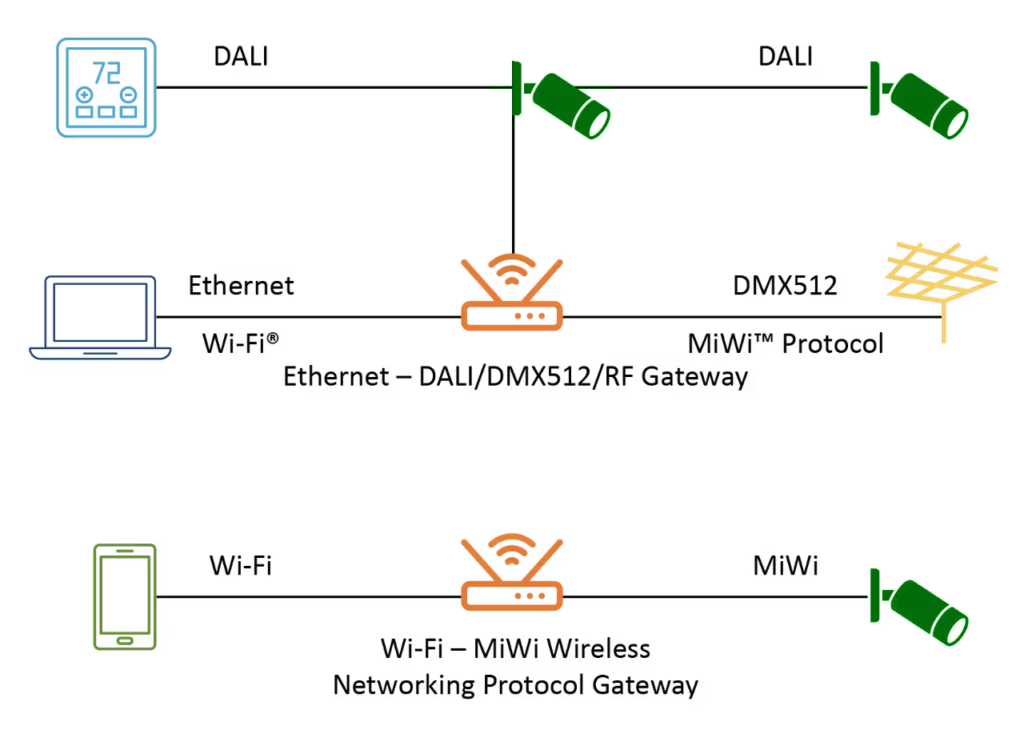

Bluetooth: Bluetooth is a short-range wireless communication technology used for data transmission and communication between devices. It features low power consumption, low cost, and simplicity and is commonly used to connect smartphones, smart devices, and sensors.

Wi-Fi: Wi-Fi is a wireless local area network communication technology used for high-speed data transmission and communication between devices. It supports remote access, internet connectivity, and is commonly used to connect computers, smart devices, and IoT devices.

These are some common communication protocols for control boards, and choosing the appropriate one based on specific application requirements and hardware platforms is crucial.

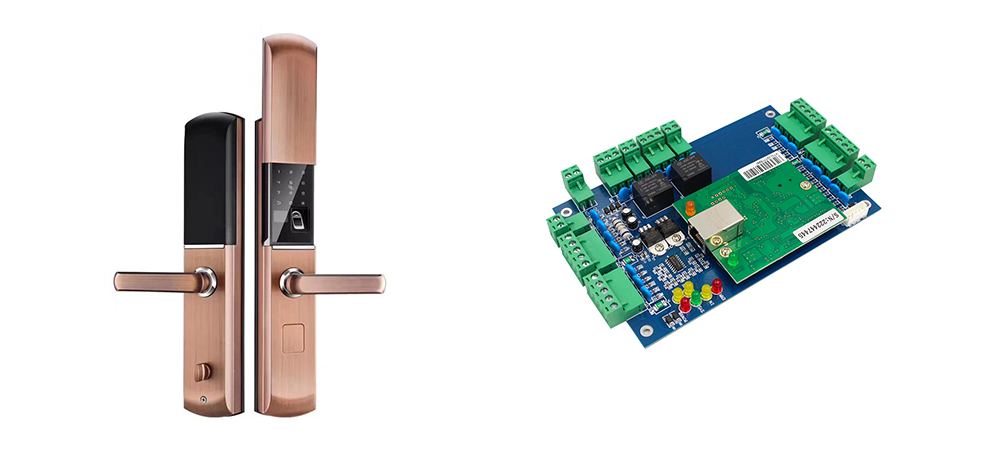

For example, the control board of fingerprint locks, which are increasingly used in many households, typically involves the following communication protocols:

- UART (Universal Asynchronous Receiver-Transmitter): UART is commonly used for serial communication between the control board and the fingerprint recognition module. The control board communicates with the fingerprint recognition module via UART to transmit data, such as sending fingerprint information for recognition and receiving recognition results.

- SPI (Serial Peripheral Interface): SPI is often used for high-speed serial communication between the control board and external memory devices (such as Flash memory). The control board of a fingerprint lock may need to exchange data with external memory devices for storing user fingerprint information, log records, etc.

- I2C (Inter-Integrated Circuit): I2C is typically used for serial communication between the control board and other peripherals (such as temperature sensors, light sensors, etc.). The control board may need to exchange data with various peripherals to monitor and control the environment.

- RS-485: RS-485 is commonly used for serial communication between the control board and the door lock motor. The control board communicates with the door lock motor via RS-485 to transmit data and control the locking actions of the door lock.

- Bluetooth: Some fingerprint locks may support Bluetooth communication for connection and data transmission with smartphones or other smart devices. Through Bluetooth communication, users can remotely control the locking actions of the fingerprint lock, manage user permissions, etc., via a smartphone app.

These are some common communication protocols that may be involved in the control board of fingerprint locks, depending on the functional requirements and design of the fingerprint lock.

Summary

That’s all for today’s relevant content. If you have any questions or collaboration needs regarding control board communication protocols or other related fields, we sincerely invite you to contact us at sales@superpcba.com. The SuperPCBA team will wholeheartedly provide you with professional consulting services and tailor the best electronic manufacturing solutions for you. Let’s work together to create the future and infuse your electronic products with even stronger performance!