As an engineer at SuperPCBA, I am thrilled to present this article on circuit board design standards, driven by passion and a sense of responsibility. In today’s rapidly evolving technological landscape, the design and manufacturing of electronic products have become a focal point for innovation and competition. Given that circuit boards are integral components of electronic products, adhering to design standards is crucial to ensuring product performance, reliability, and continuous innovation.

In this article, we will delve into internationally recognized standards for circuit board design. From the perspective of understanding the importance of adhering to these standards, we will analyze in-depth how compliance contributes to enhancing product quality, reducing risks, and ultimately standing out in the fierce market competition.

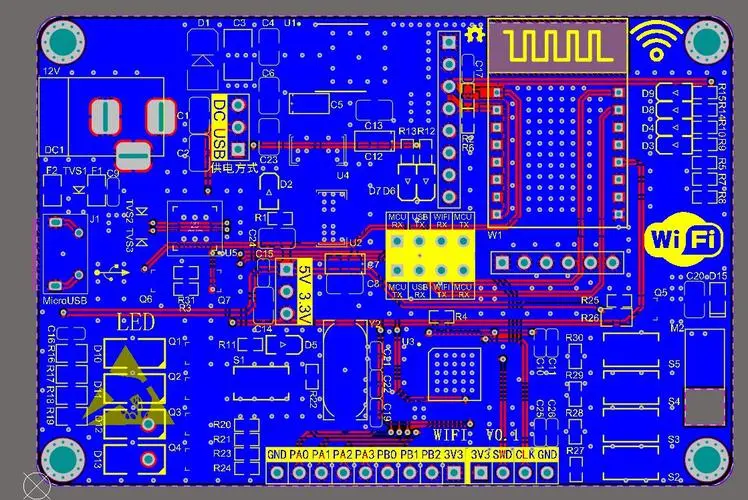

PCB Design Standards: Ensuring Excellence in Circuit Board Design

PCB (Printed Circuit Board) design standards are a set of specifications and guidelines established to ensure that circuit board designs meet specific quality, manufacturability, and reliability criteria. From a product perspective, gaining insights into and understanding PCB design standards helps to guarantee the quality of circuit board products, enhance their reliability, and contribute to improved interoperability among electronic devices. From a production standpoint, adhering to these standards can boost manufacturing efficiency, reduce costs, and enhance product maintainability. These standards are developed by international organizations such as the International Electrotechnical Commission (IEC), the Institute of Electrical and Electronics Engineers (IEEE), and are typically released by industry groups or the International Organization for Standardization (ISO).

Taking IPC-2221B as an example, these standards encompass various specifications to ensure that PCB designs meet requirements for performance, reliability, and manufacturability. Here are some key aspects and examples from IPC-2221B:

Material Requirements:

- Specifies requirements for materials used in PCB manufacturing, including substrate materials and coatings.

- Example: Specifies the glass transition temperature (Tg) and coefficient of thermal expansion for the substrate.

Testability:

- Emphasizes the design’s testability for ease of testing and troubleshooting during the manufacturing process.

- Example: Specifies the layout and design of test points for easy access to critical circuit nodes.

Thermal Management and Heat Dissipation:

- Provides guidelines on managing heat on the PCB and designing heat dissipation devices when necessary.

- Example: Specifies the design of heat sinks to maintain proper temperature in high-power applications.

Annular Rings:

- Describes guidelines on considering and using annular rings in the design. Annular rings are circular areas between electronic component pins and PCB pads.

- Example: Specifies the minimum width of annular rings and their relationship with holes.

Interlayer Insulation:

- Specifies insulation requirements between different layers in multilayer PCBs to ensure electrical performance and prevent interlayer short circuits.

- Example: Specifies the minimum requirements and testing methods for interlayer insulation.

Trace Width and Spacing:

- Includes regulations for trace width and spacing to ensure the circuit meets design requirements.

- Example: Specifies trace widths and spacings under different current loads.

Pin Spacing:

- Describes minimum spacing requirements between component pins to ensure adequate insulation and prevent pin short circuits.

- Example: Specifies the minimum pin spacing for different pin packages.

Pad Design:

- Includes design requirements for pads to ensure reliable solder connections.

- Example: Specifies the shape, size, and alignment requirements for pads concerning component pins.

These examples represent only a portion of the IPC-2221B standard. These specifications and guidelines play a critical role throughout the entire process of PCB design and manufacturing. Designers and manufacturers can use these standards to guide their work, ensuring that PCBs exhibit high performance, reliability, and manufacturability.

Common PCB Design Standards

IPC Standards:

- IPC-2221: Electrical design standard covering general provisions, performance characteristics, and dimensional standards in PCB design.

- IPC-6012: Manufacturing standard defining requirements for multilayer printed circuit boards, including materials, interlayer insulation, trace width, and spacing.

- IPC-7351: Surface Mount Device (SMD) design standard specifying packaging and layout requirements for surface-mounted components.

IEEE Standards:

- IEEE 802.3: Ethernet standard specifying hardware requirements for network devices, including PCB design and wiring specifications.

- IEEE 1076: VHDL (Hardware Description Language) standard used to describe the behavior and structure of digital circuits.

ISO Standards:

- ISO 9001: Quality management system standard, although not specifically for PCB design, widely applied in the electronics manufacturing industry to ensure quality management in product design and manufacturing.

JESD Standards:

- JESD47: Reliability test standard for high-temperature, high-humidity, and high-reliability electronic products, particularly crucial for PCB designs requiring high reliability.

Customer Specifications: Some industries or companies may have their own standards and specifications. Designers should be familiar with and adhere to these regulations.

The Significance of Studying PCB Design Standards

Understanding the significance of PCB design standards lies in ensuring that the processes of designing, manufacturing, and testing circuit boards meet specific standards of quality, reliability, and performance. These standards provide a series of guidelines and criteria for designers, manufacturers, and testing personnel to ensure that circuit boards meet specific requirements in various aspects. Therefore, we can summarize the following key significances of understanding PCB design standards:

- Ensuring Quality: PCB design standards specify requirements in various aspects, including material selection, trace layout, welding standards, etc., to ensure a consistent quality level in the manufacturing of circuit board products. This helps reduce defects during the manufacturing process and enhances product reliability.

- Improving Reliability: Standards provide detailed specifications for the design and manufacturing processes of circuit boards, helping to minimize failures caused by improper design or manufacturing defects, thereby improving product reliability. Reliable circuit board design is crucial for applications with high reliability requirements, such as medical devices, aerospace, and automotive electronics.

- Promoting Interoperability: Standards ensure interoperability between electronic devices, enabling devices from different manufacturers to work together seamlessly. This is particularly important for integrating various electronic components in complex systems.

- Enhancing Manufacturing Efficiency: Standardized design and manufacturing processes contribute to improved manufacturing efficiency. Designers and manufacturers can operate according to standards, reducing the chances of errors and rework, thereby enhancing production efficiency.

- Cost Savings: Standardized design and manufacturing processes help lower manufacturing costs. Designers can choose commonly used materials and processes based on standards, while manufacturers can more easily implement automated and standardized production processes, reducing production costs.

- Improving Maintainability: Standards prescribe easily maintainable and repairable design and manufacturing methods, helping reduce costs and risks when equipment needs maintenance or upgrades.

- Ensuring Compliance: Some standards may involve requirements related to regulations and compliance for different industries and markets. Understanding and adhering to these standards ensure product compliance in international markets.

Overall, understanding PCB design standards helps establish a common set of norms, providing a unified framework for the entire electronics industry, thereby driving technological development, improving product quality, and fostering market competitiveness.

Conclusion

Through this article, we hope you have gained a deeper understanding of the benefits that come with learning and adhering to circuit board design standards in the manufacturing of electronic products. SuperPCBA is committed to providing circuit board design and manufacturing services that comply with the highest international standards. We recognize the crucial role that standard compliance plays in ensuring our customers receive products of high quality and strong reliability.

If you have further questions about circuit board design standards or any other related areas, or if you are interested in our company’s services, please feel free to contact us. The SuperPCBA team is dedicated to providing professional consultation to assist you in achieving excellence in the design and manufacturing of electronic products.

Let’s collaborate to create excellence and ensure the success of your electronic products!