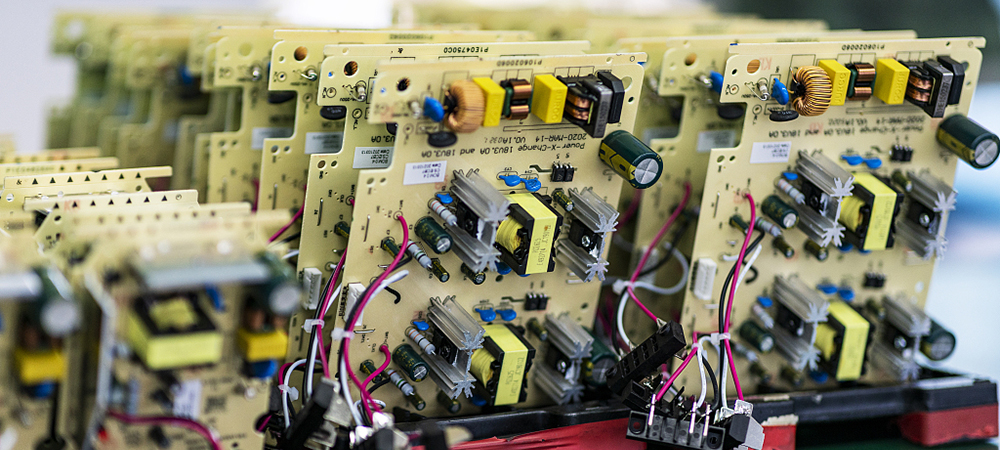

Turnkey PCB assembly refers to a comprehensive service where a PCB assembly provider takes full responsibility for the entire assembly process, from sourcing components to final product delivery.

Why does it called “Turnkey PCB Assembly Services”?

I believe many people, just like myself, are curious about “Turnkey PCB Assembly” name and wonder why “Turnkey PCB Assembly” service is called by this particular name. So, let’s delve into the origins of “Turnkey PCB Assembly” and satisfy our curiosity.

This term is borrowed from the construction industry. A turnkey project in the context of building construction refers to a comprehensive approach where a single entity, typically a construction company or contractor, takes full responsibility for the entire project, from design and planning to construction and final delivery. In a turnkey project, the client provides the requirements and specifications, and the contractor handles all aspects of the project, including design, engineering, procurement, construction, and commissioning.

In the case of PCB assembly, the term “turnkey” signifies that the service provider assumes full responsibility for managing the entire process, including component sourcing, procurement, manufacturing, quality control, testing, and even logistics. They handle everything from the initial design review to the final delivery of the assembled PCBs. The name “turnkey PCB assembly service” reflects the idea that customers can essentially “turn the key” and have a fully assembled and functional PCB without having to worry about the intricate details and management of the assembly process. It implies a complete and hassle-free service where the customer can rely on the expertise and capabilities of the PCB assembly provider to handle all aspects of the project.

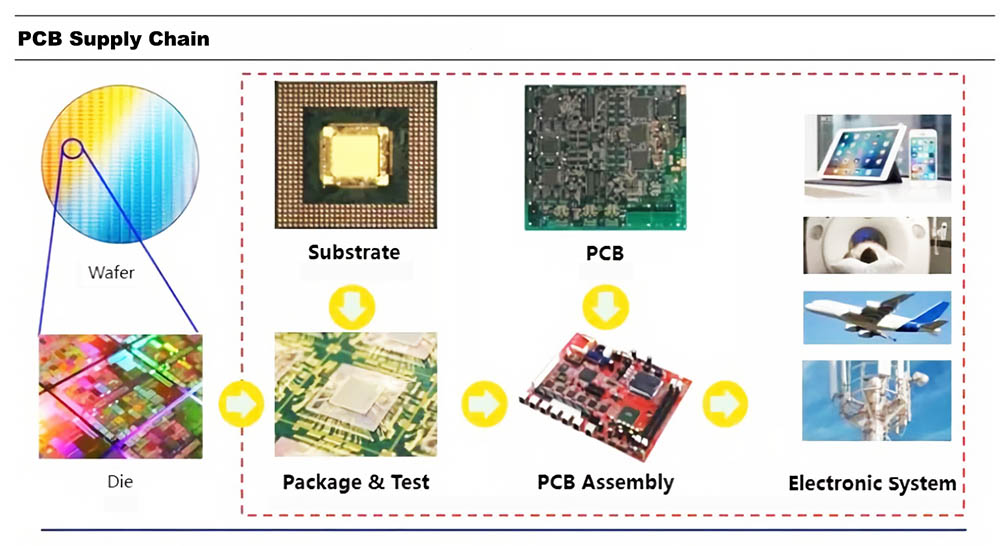

How Does Turnkey PCB Assembly Service Streamline Your Supply Chain?

Turnkey PCB assembly offers a streamlined approach to PCB manufacturing, simplifying the supply chain, reducing costs, and providing expertise and support throughout the process. It enables customers to focus on their core competencies while benefiting from the efficiency, cost savings, and quality assurance the PCB assembly provider provides.

Simplified Supply Chain Management:

With turnkey PCB assembly, the PCB assembly provider handles all aspects of the supply chain, including component sourcing, procurement, and inventory management. This eliminates the need for the customer to engage with multiple suppliers, reducing complexity and administrative tasks. It streamlines the supply chain by consolidating all procurement activities under one provider, saving time and effort.

Time and Cost Savings:

Turnkey PCB assembly can significantly reduce the time and cost associated with managing multiple suppliers and procurement processes. The PCB assembly provider leverages their expertise, industry connections, and bulk purchasing power to source components at competitive prices. They also have established relationships with reliable suppliers, reducing the risk of delays, counterfeit components, or quality issues. These factors contribute to cost savings and faster turnaround times for PCB assembly projects.

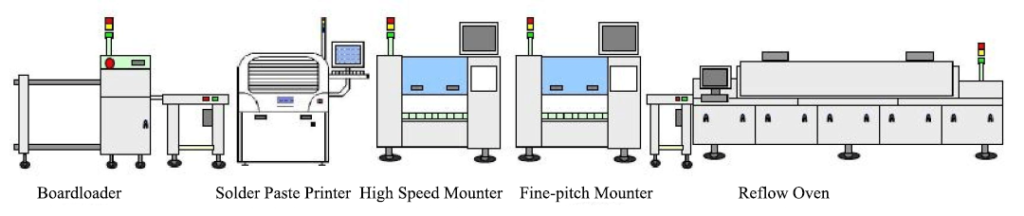

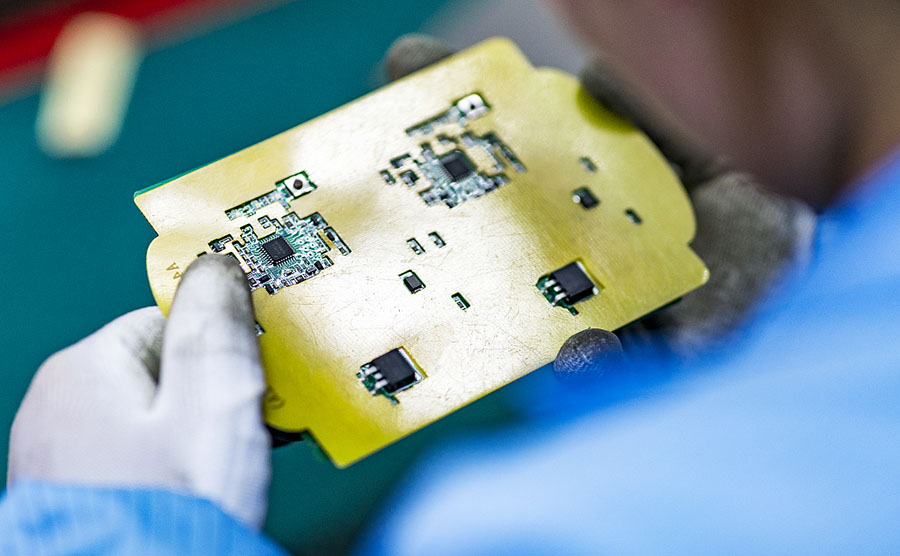

Expertise and Manufacturing Capabilities:

PCB assembly providers offering turnkey services have specialized expertise and state-of-the-art manufacturing capabilities. They are equipped with advanced equipment, experienced personnel, and quality control processes to ensure efficient and high-quality assembly. By relying on their expertise, customers can benefit from optimized manufacturing processes, improved yield rates, and reduced risk of errors or defects.

Design for Manufacturability (DFM) Optimization:

Turnkey PCB assembly providers often offer design for manufacturability (DFM) services. They can review the customer’s PCB design files and suggest design optimizations to enhance manufacturability, reliability, and cost-effectiveness. By identifying potential design issues early on, such as component placement, routing, or manufacturing constraints, DFM optimization ensures smoother assembly and reduces the likelihood of rework or delays.

Seamless Project Management:

Turnkey PCB assembly providers act as a single point of contact for the entire assembly process. They manage all aspects of the project, from coordinating with suppliers to handling logistics, quality control, and delivery. This centralized project management simplifies communication, reduces coordination efforts, and ensures a smooth workflow from start to finish.

Risk Mitigation and Quality Assurance:

By entrusting the assembly process to a reputable turnkey provider, customers benefit from enhanced risk mitigation and quality assurance. The PCB assembly provider is responsible for ensuring that all components are sourced from reliable suppliers and meet the required quality standards. They perform rigorous quality control inspections, testing, and certifications to ensure the final product’s reliability and functionality.

How to Manage A Turnkey PCB Assembly Order?

When placing a turnkey PCB assembly order with a Chinese PCBA factory, there are several important factors to consider to ensure a smooth and successful collaboration. Here are 10 key points to pay attention to:

Factory Reputation and Reliability:

Research the reputation and reliability of the Chinese PCBA factory before placing an order. Look for reviews, customer feedback, and certifications to gauge their track record and quality of service. Consider their experience in handling similar projects and their ability to meet deadlines.

Clear Communication:

Establish clear and effective communication channels with the PCBA factory. Ensure they understand your requirements, specifications, and project expectations. It’s crucial to have a mutual understanding of technical details, documentation, and any special considerations related to your PCB assembly order.

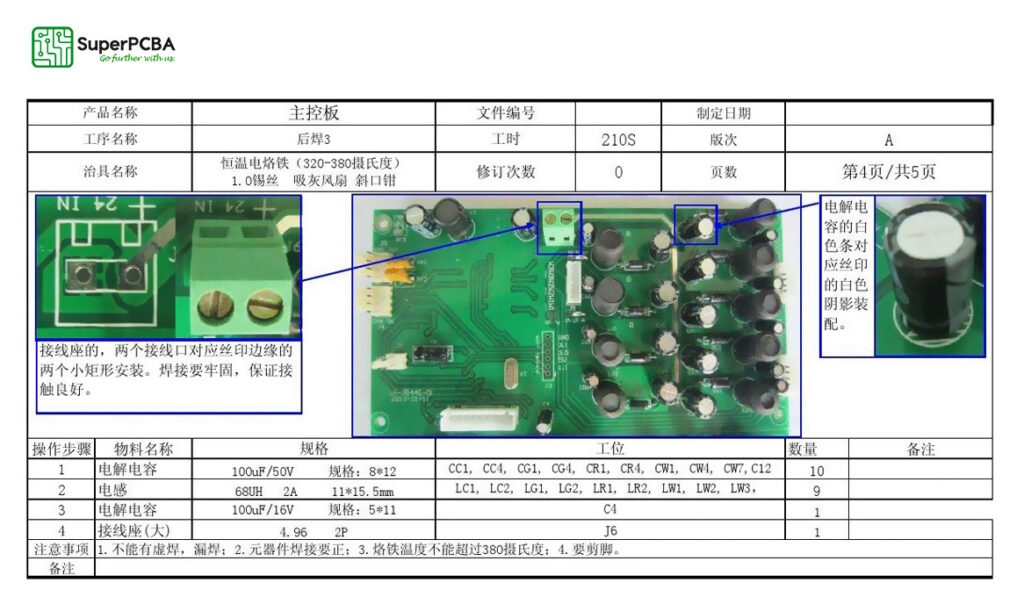

Quality Control Measures:

Inquire about the PCBA factory’s quality control measures and certifications. Ensure they have robust quality control processes in place, including inspections, testing, and adherence to industry standards (such as ISO 9001). Ask for samples or references to evaluate the quality of their previous work.

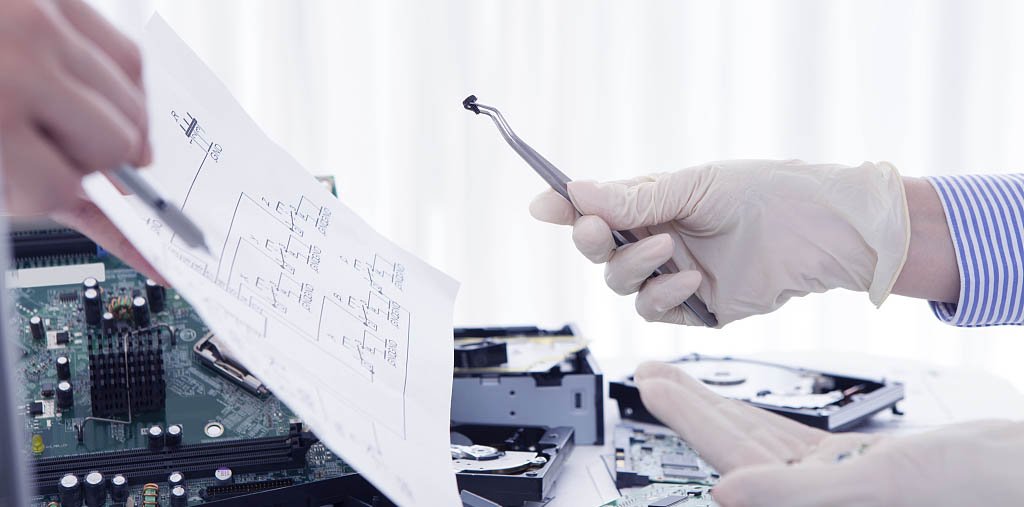

Component Sourcing and Verification:

Discuss component sourcing with the factory. Ensure they have access to a reliable supply chain and can source genuine and high-quality components. Request information about their component verification process to minimize the risk of counterfeit or substandard components.

Manufacturing Capabilities and Capacity:

Assess the PCBA factory’s manufacturing capabilities, equipment, and capacity to handle your order size and complexity. Consider factors such as their production capacity, lead times, and flexibility in accommodating your specific requirements. Verify if they have experience with the specific technologies, materials, or assembly techniques relevant to your project.

Intellectual Property Protection

Protecting your intellectual property (IP) is crucial. Discuss and clarify IP ownership and confidentiality agreements with the PCBA factory. Ensure they have proper measures in place to safeguard your designs, documentation, and any proprietary information associated with your project.

Logistics and Shipping:

Discuss logistics and shipping arrangements with the PCBA factory, it’s better to sign a contract. Clarify responsibilities and expectations regarding packaging, labeling, customs documentation, and delivery timelines. Consider any potential customs duties, taxes, or import/export regulations that may apply.

Cost and Payment Terms:

Understand the cost structure and payment terms offered by the PCBA factory. Obtain a detailed quote that includes all relevant costs, such as component sourcing, assembly, testing, and shipping. Clarify payment terms, such as upfront deposits, milestones, or final payment upon completion.

Overall, the term “turnkey PCB assembly service” encapsulates the comprehensive and all-inclusive nature of the service, highlighting the convenience, efficiency, and peace of mind it offers to customers by taking care of the entire assembly process from start to finish.

At SuperPCBA, we offer comprehensive turnkey PCB assembly services that streamline your supply chain and simplify your manufacturing process. We are expecting to discuss your upcoming PCB assembly needs with us and how our turnkey services can benefit your business. We can provide detailed pricing and lead time information within 24 hours!