Refrigerator plays a crucial role in preserving the freshness and safety of food and drinks, and is an essential appliance in many households and commercial settings.

a refrigerator system is a type of refrigeration equipment that uses a refrigerant to remove heat from the inside of a refrigerator or freezer, keeping its contents cool. The system works by circulating the refrigerant through a closed loop system of tubes and coils, which absorb heat from the interior of the refrigerator and transfer it to the outside. The refrigerant then goes through a phase change from a liquid to a gas, absorbing heat during the process, and then goes through a compressor to be compressed back into a liquid, releasing the absorbed heat.

The refrigerator system also includes a thermostat that senses the temperature inside the refrigerator and turns the compressor on or off as needed to maintain a desired temperature range. Some advanced refrigerators may also have additional features such as defrost cycles, adjustable shelves, and water dispensers.

To guarantee the refrigerator system work well, we must guarantee there is good designed and assembled PCB board for refrigerator.

The PCBA board of a refrigerator system is responsible for controlling and monitoring the temperature inside the fridge and ensuring the proper functioning of various components such as the compressor, fan, and defrost system. Here are some factors to consider when designing a PCBA board for a refrigerator system:

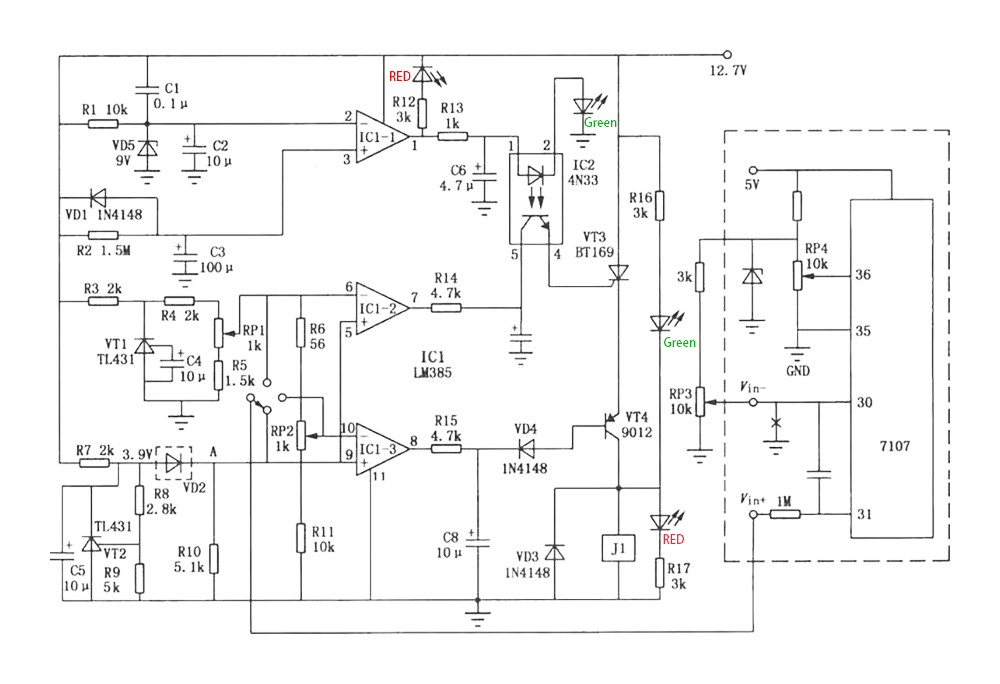

- Temperature sensors: The PCBA board should include temperature sensors that can accurately measure the temperature inside the fridge and freezer compartments. Typically, thermistors are used as temperature sensors for refrigerators.

- User interface: The PCBA board should have an easy-to-use interface for the user to adjust the temperature settings and other features of the fridge.

- Compressor control: The compressor is responsible for cooling the refrigerator, and the PCBA board should include a relay or other device that can turn the compressor on and off as needed to maintain the desired temperature.

- Fan control: The PCBA board should also include a relay or other device to control the operation of the fan, which circulates the cold air throughout the fridge.

- Defrost control: To prevent frost buildup on the evaporator coils, the control board should include a defrost system that can turn on a heater or other device to melt any ice that has formed.

- Safety features: The PCBA board should include safety features such as over-temperature protection, short-circuit protection, and over-current protection to prevent damage to the fridge and ensure user safety.

- Power supply: The PCBA board should be designed to operate on the appropriate voltage and current supply used by the fridge. It should also be designed to protect against power surges and other electrical disturbances.

- Compatibility: The PCBA board should be designed to be compatible with the other components of the refrigerator system, such as the compressor, fan, and defrost system.

Compressor control is a critical aspect of the refrigeration system PCBA board design for a refrigerator. The compressor is the heart of the refrigeration system, and its performance and control are essential for maintaining the temperature and cooling of the fridge.

The compressor is usually controlled using a relay that is connected to the PCBA board. The relay is controlled by a microcontroller that receives input from various sensors such as the thermostat, temperature sensors, and pressure sensors. The microcontroller analyzes the input and decides whether to turn the compressor on or off.

To ensure efficient and safe operation of the compressor, the PCBA board should incorporate several features, such as:

- Overload protection: The PCBA board should monitor the compressor’s current and protect it from overload, which can cause damage or even failure.

- Short cycle protection: The PCBA board should prevent the compressor from starting and stopping too frequently, which can cause wear and tear on the compressor.

- Delay start: The PCBA board should incorporate a delay start feature to ensure that the compressor does not start immediately after shutting down. This delay helps to prevent damage to the compressor and extends its lifespan.

- Soft start: The PCBA board should include a soft start feature that gradually increases the compressor’s speed and reduces the current surge that occurs during startup. This feature helps to extend the compressor’s lifespan and reduce stress on the electrical system.

By incorporating these features into the compressor control, the refrigeration system can operate more efficiently and reliably, leading to longer lifespan and lower maintenance costs.

Besides, defrost control is also an important function in a refrigerator system PCBA board. When the refrigerator operates, frost may accumulate on the evaporator coil, which can reduce the cooling efficiency of the refrigerator. Therefore, it is necessary to periodically defrost the evaporator coil.

The defrost control function in a refrigerator system PCBA board typically involves monitoring the temperature and humidity of the evaporator coil to determine when to initiate a defrost cycle. There are several methods for defrosting the evaporator coil, such as using a heater or hot gas to melt the frost. The control board must accurately control the defrost cycle to ensure that it is effective in removing the frost, while also minimizing the amount of time that the refrigerator is not operating.

Proper defrost control is crucial to ensure the efficiency and longevity of a refrigerator system. Without adequate defrosting, the evaporator coil can become completely covered in frost, which can eventually lead to compressor failure and other costly repairs.